Draft day derby: The wild world of picking an NFL quarterback

The 2024 NFL draft begins Thursday, April 25, and will be full of intrigue for NFL fans. For teams near the bottom of the standing, the draft represents hope for the future. The right player can turn...

Peter_Hersh

Peter_Hersh

Masukawa_Nao

Masukawa_Nao

Paul_Nelson

Paul_Nelson

gail_massari

gail_massari

Jed_Campbell

Jed_Campbell

Phil_Kay

Phil_Kay

Bill_Worley

Bill_Worley

DaeYun_Kim

DaeYun_Kim

SamGardner

SamGardner

Valerie_Nedbal

Valerie_Nedbal

Richard_Zink

Richard_Zink KristenBradford

KristenBradford

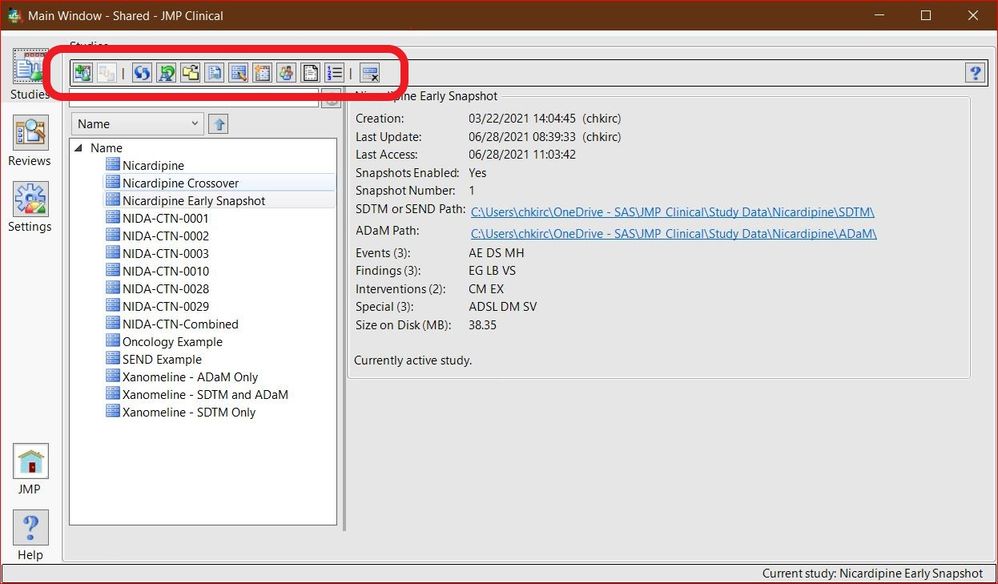

Chris_Kirchberg

Chris_Kirchberg

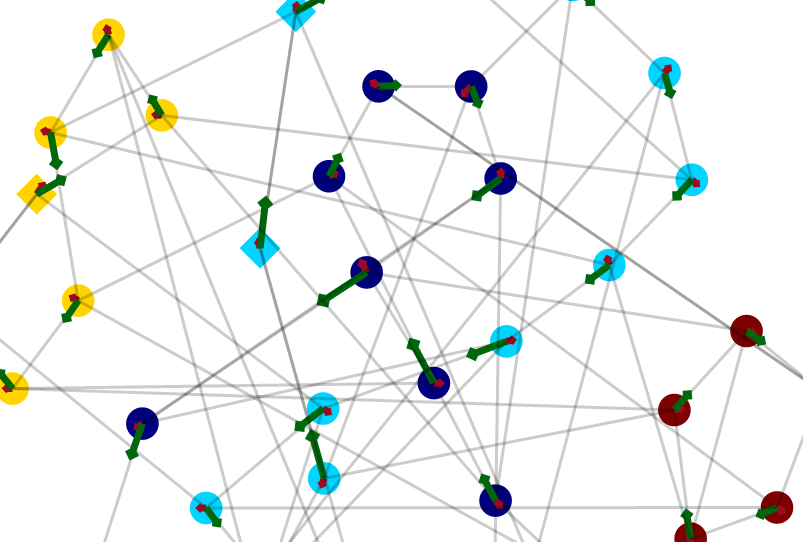

cweisbart

cweisbart

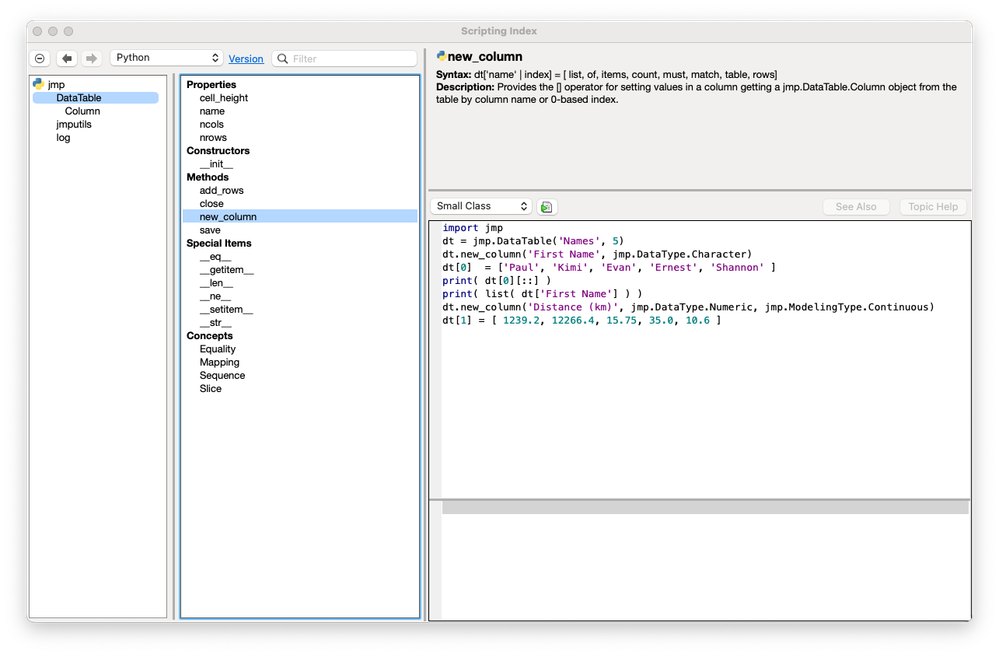

Craige_Hales

Craige_Hales

anne_milley

anne_milley

Di_Michelson

Di_Michelson