JMP Blog

A blog for anyone curious about data visualization, design of experiments, statistics, predictive modeling, and more- JMP User Community

- :

- Blogs

- :

- JMP Blog

- :

- 什麼是SPC(統計製程控制)?減少製程變異的分析流程解說與數據解讀

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

實現卓越製造是每個企業追求的⽬標。為了達到這個⽬標,品質部門必須不斷努⼒識別製程變化的來源,並採取適當的措施來控制⽬標。時至科學化的現代,品質單位已經可以透過數據分析的方式,來理解製程的⽣產過程,不僅可以增加⽣產的靈活性,⽽且能確保產品更好地符合客戶要求。

實現智慧製造的三大關鍵

如何基於科學的數據分析實現卓越製造,更是每家企業在要求提升產品品質時,所面臨到的問題。透過過去JMP合作的產業案例可以看出,企業實現卓越製造需要經歷三個關鍵過程:

- 1.透過控制圖及製程能力分析,實現統計製程管制 (SPC),減少製程變異;

- 透過測量系統分析 (MSA),尋找測量過程中的變異源;

- 透過實驗設計(DOE) 及預測建模,確定對測量變異有影響的因⼦,找到因⼦的最佳設置,使測量過程更加穩健。

我們以⼀個醫藥⽣產製造商的案例看看如何實施這「數據分析三部曲」。⾸先,我們先來看看如何進行統計製程管制(SPC)。

實戰案例分析

製程背景

FVM製藥公司是⼀家國際藥品製造商,專門⽣產⾼品質的成品配⽅藥,產品類型包括片劑、膠囊和液體。在製藥過程裡,有個典型的製造過程包括:將活性藥物成分(API)研磨成均勻顆粒⼤⼩的粉末,接著將磨碎的材料與其他組分混合,使原料藥體積變⼤並均勻分佈,然後將這種混合材料壓製成片劑,最後進⾏包衣,以提⾼有效期限、⼝感和其他性能。在這個過程結束時,各種品質參數指標都會被記錄,以便批量驗收。

上述過程的原材料是含有兩種有機化合物的濃縮乳劑,由兩個供應商(A,B)同時提供,製藥公司透過氣相⾊譜法(GC)測量化合物的濃度(mg/L)來監測品質。

現況問題

最近品質管理團隊發現藥品品質存在很⼤的差異,透過問題排查,懷疑問題有很⼤可能來⾃原料藥。為此,公司專門成立品質改進⼩組,希望藉助統計⼯具,結合品質源於設計⽅法(QbD),透過數據化決策,從根本上找到⼀個可持續的解決⽅案,確定製程變化的關鍵驅動因素,最終達到優化製程設置的目的。

改善過程

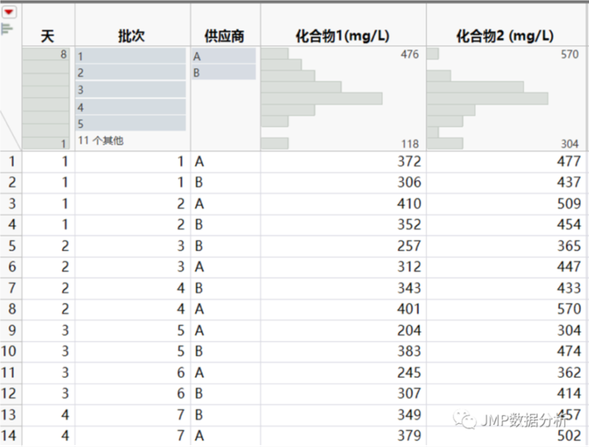

首先,品質改進⼩組進⾏產品的統計製程管制 (SPC)。透過控制圖瞭解製程的穩定性並分析過程變化的模式。透過製程能力分析,評定其是否滿⾜顧客/外部交期。兩個⼯具都⽀持更好地理解過程,並指導制定改進策略。團隊對來⾃兩家供應商的兩種化合物原材料,進⾏了為期8天的樣品採集並導入JMP軟件,涉及所有批次,下圖(一)為部分數據截圖。

圖 (一)

分析的先決條件:檢視數據是否呈現常態

許多品質統計⼯具使⽤的前提假設是數據來⾃於常態分佈,否則基於平均值和標準差的報告結果就沒有意義。利⽤ JMP選單,點選「分析 (Analyze)à 分佈平臺 (Distribution)」,結合SW檢驗和AD檢驗結果,可以確認兩個化合物數據呈現常態分佈,表示沒有問題,結果如下圖(二)所⽰。

圖(二)

當然,也可以透過分析 (Analyze) à 分佈平台 (Distribution) 的互動功能(點選某個參數的某個⽔平,其他參數對應部分也會被選中),快速查看三個參數“天”、“批次”和“供應商”作為可變性潛在驅動因素與兩種化合物的變化關係,如圖(三)。

例如每天都會使⽤來⾃兩個供應商的批次,但即使同⼀天的批次,化合物1和化合物2的結果也差異巨⼤。

圖(三)

分析第二步驟:檢視數據是否產生變異

完成常態檢定和直⽅圖分析後,就可以使⽤ JMP 控制圖⽣成器平臺(Control Chart Builder)探索品質⽅⾯的問題了。由於變異存在於任何系統和過程當中,控制圖能⾃動計算的控制限,便能有效區分過程變異中⼀般原因和特殊原因產⽣的變異,從⽽識別和消除特殊原因造成的數據波動。

另⼀個常⽤的品質工具 — 製程能力分析 (Process Capability),可以有效衡量⼀個製程與給定的規格限相比表現如何,有助於識別表現不佳的過程。計算時⽤到的規格限,是由外部系統或按過程要求設定的。本例中化合物1的規格下限和上限分別是100mg/l和500mg/l,化合物2的規格下限和上限是300mg/l和600mg/l。

⼀個好的過程是⼀個穩定的過程,並且持續地⽣產出遠在規格限之內的產品。上述兩個⼯具Control Chart Builder & Process Capability便是經常結合使⽤,⽤於評估製程的穩定性以及評估其滿⾜客戶規格要求的能⼒。

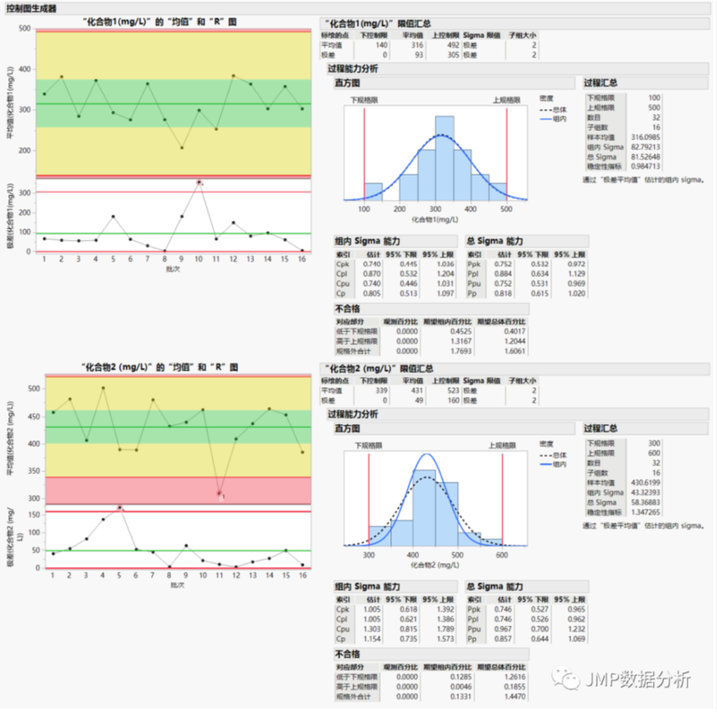

透過JMP的控制圖⽣成器平台可以快速得到下圖(四)的輸出結果,左側分別為化合物1和化合物2的XBar&R控制圖,右側為製程能力分析結果。

圖(四)控制圖⽣成器結果

分析第三步驟:分析結果的數據解讀

- XBar圖是以批次為⼦組的均值控制圖。觀察可以發現,化合物1的所有的點都隨機落在控制範圍內(綠⾊和黃⾊區域)。引入判異規則,沒有任何點被圈起來或被標記,這意味著過程是"在控制中"或穩定的。⽽化合物2在引入判異規則後,發現批號11落入紅⾊區域,並被圈起來或打上標記,這表明該過程不受控制或不穩定。

- R圖是批次為⼦組的極差控制圖,⽤於監測過程中的波動⼤⼩。圖表上的每個點都代表批次範圍的最⼤值和最⼩值的差值。引入判異規則,可以看到化合物1的第10批產品和化合物2的第5批超出了控制限,說明有⼀些特殊原因造成過程波動變化。

- 右側部分則是製程能力分析結果,⽤來識別表現不佳的過程。常⽤來評估的幾個能⼒指標包括:

- Cp/Pp:規格限的寬度與過程波動之比。Cp⼜叫內部(或短期)潛在製程能力( 只考慮⼦組內的波動),Pp⼜叫整體(或⻓期)潛在製程能力(考慮所有組整體的波動)。它們是衡量如果過程均值和⽬標均值⼀致,能⼒能夠達到多少的常⽤指標;

- Cpl/Ppl:⽤于檢查⼀個過程滿⾜規格下限的能⼒;

- Cpu/Ppu:⽤于檢查⼀個過程滿⾜規格上限的能⼒;

- Cpk/Ppk:取Cpl/Ppl和Cpu/Ppu的最⼩值。

- Cpk/Ppk等於1.0,被認為⼀個勉強合格的過程,當然也有些⾏業準則要求Cpk/Ppk的最⼩值為1.33或甚⾄更⾼。

- 當前原料化合物1的Cpk值和Ppk值分別為0.740和0.752,所以認為該製程不太合格。化合物2也不是很好,Cpk值和Ppk值分別為1.005和0.746。

分析第四步驟:從供應商角度探索變異來源

把供應商拖到控制圖的頂部(階段區),可按供應商分割控制圖,如下圖 (五) 所⽰。

圖(五)

從上圖(五)可以看出,對於這兩種化合物,基於現有控制限,雖然供應商A提供的這兩種化合物都很穩定(批次在控制限度內),但是我們可以發現:供應商A明顯比供應商B有更⼤的批次間變化。供應商B批次間的變化相對比較⼩,但發現供應商B的化合物1表現出特殊原因的變異。

此外,我們也可嘗試使⽤模型驅動的多元控制圖(MDMVCC),利⽤主成分分析(PCA)在⼀個控制圖中監測多個製程的參數。在某些場景下,如果只是獨立觀察各個製程,似乎都是穩定的,透過多元控制圖可以同時檢測多個過程的潛在不穩定性,深入調查個別過程對整體性的貢獻,以診斷製程是否穩定。

圖(六)

由上圖(六)可知供應商A的所有批次都在控制限內,⽽對於供應商B,可以清楚地看到三個批次是失控點,需要關注。

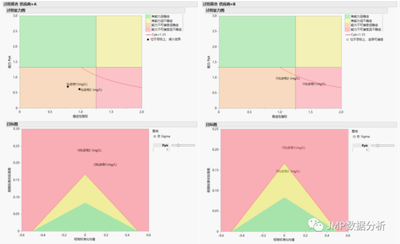

此外,我們還可以透過JMP製程能力篩選平台(Process Screening),利⽤⽬標圖和製程性能圖將變異和能⼒結合到⼀個輸出中,同時查看兩個供應商的化合物是否穩定,是否符合給定規格。此平台尤其適合⼤量製程需要監測的品質檢測場景,非常推薦使用。

圖(七)

上圖(七)的製程能力圖突出了過程是否健康的兩個⽅⾯, 即穩定性指標和製程能力(Ppk)。⼀個穩定的過程將有⼀個接近1的穩定性指標。穩定性指數的值越⾼,表明製程越不穩定。

製程能力Ppk是衡量過程表現的重要參數,數值越⾼,對應於每百萬個產品的缺陷率越低。理想的製程(有能⼒的和穩定的)顯⽰在圖中的綠⾊陰影區域,其中Ppk>1.0, 穩定指數<1.25。無能⼒的和不穩定的過程在紅⾊陰影區域,其中Ppk<1.0,穩定指數>1.25。

⽬標圖為每個過程在 x 軸上顯⽰規格標準化的均值偏移,在 y 軸上顯⽰規格標準化的標準差,⽤於快速提供關於過程是否符合規格限的匯總視圖。

穩定有能⼒的製程顯⽰在圖中的綠⾊(pk>2.0)和黃⾊(pk>1.0)陰影區域,⽆能⼒的和不穩定的過程在紅⾊陰影區域(Ppk<1.0)。

對於供應商A來說,化合物1和化合物2的兩個過程都是穩定的,但能⼒不⾜。對於供應商B來說,化合物2是穩定的,但能⼒不⾜,⽽化合物1既能⼒不⾜⼜不穩定。

階段性結論和品質改善方案

我們接連使⽤了均值、極差控制圖和多元控制圖等方式,來監測供應商的原材料品質和關鍵製程參數,並要求供應商也使⽤這些控制圖來減少製程過程變異。

理論上,如果供應的原材料不穩定,所有供應批次都應該被監測,並增加原材料抽樣分析的頻率,不過⽬前還不能實現,因為現有的氣相⾊譜分析⽅法(GC)非常花時間,全檢將無法滿⾜⽣產的需求。所以⽬前正在開發的快速分析⽅法,超⾼效液相⾊譜法(UHPLC),將是下⼀步⼯作的重點。如何透過超⾼效液相⾊譜測量系統來實現更快的原材料品質監測?我們將在之後的⽂章中繼續探索。

如對⽂中統計製程控制(SPC)統計⽅法感興趣的朋友,歡迎下載最新版JMP 親⾃體驗。瞭解更多資料分析知識與技巧。

推薦閱讀:

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.