- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- RE: Gauge R&R Definitions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

RE: Gauge R&R Definitions

Hi,

I am conducting a Gauge R&R study for the first time for a measurement system. I have a few questions.

1. In the attached sample report, there're two Gauge R&R numbers circled in red and blue. It looks like the blue accounts for operator and measurement variations while the red in addition accounts for part variations. Which of the two numbers apply to the "0 - 10% excellent, 10 - 20% adequate, 20 - 30% acceptable, >30% unacceptable"? Or they're both applicable?

2. How do I select K, the sigma multiplier? It looks K is proportional to all the variations but the overall %Gauge R&R doesn't change. We don't have a 6 sigma process. What do I base on to select this factor?

Thanks,

Gary

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

RE: Gauge R&R Definitions

The guidance about evaluating Gauge R&R applies to the estimate circled in red.

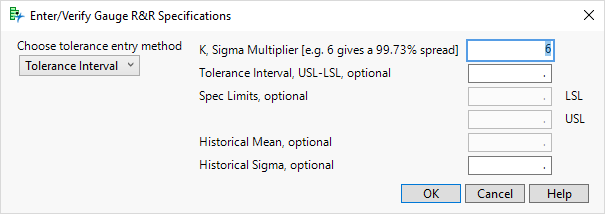

Click the red triangle at the top of the platform and select Gauge Studies > Gauge R&R. You are presented with a dialog box:

The multipliier k is the first parameter with a default value of 6.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

RE: Gauge R&R Definitions

The guidance about evaluating Gauge R&R applies to the estimate circled in red.

Click the red triangle at the top of the platform and select Gauge Studies > Gauge R&R. You are presented with a dialog box:

The multipliier k is the first parameter with a default value of 6.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

RE: Gauge R&R Definitions

Thanks Mark for clarifying.

Regarding my second question, I'm more asking what's the rationale behind JMP using 6? I've also heard that 5.15 is used in some practice. Can I change this sigma multiplier to any arbitrary number like 3?

Gary

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

RE: Gauge R&R Definitions

The multiplier depends on where you practice. For example, companies that follow the AIAG standard will use k = 5.15, but not everyone does.

Yes, you can enter any multiplier in the dialogl.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

RE: Gauge R&R Definitions

One statistic people look at to assess the goodness of their gauge is the Precision to Tolerance (P/T) Ratio.

P/T ratio = (k x gage sigma) / tolerance

The value for k is typically driven by a company's standard operating procedure or by the company's customers or suppliers or industry standard.

The intent is to use a value such that k x gage sigma is the "width" of the gage sigma distribution which can be compared to the with of the tolerance.

Some people like to use k=6 because it is simple and they like to use a +/- 3-sigma width which represents 99.7% of the values.

Some people like to use k=5.15 because that represents 99% of the values. They like to use 99% because that's simple for them.

Kinda a matter of personnel preference.

We used to use 5.15 in our company, it was pretty standard across our divisions. But, more recently, we switched to k=6 because to standardize with a few key suppliers and customers.

It is important to know which k you are using. But more important to standardize within your company to that everyone is using the same value.

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us