- JMP will suspend normal business operations for our Winter Holiday beginning on Wednesday, Dec. 24, 2025, at 5:00 p.m. ET (2:00 p.m. ET for JMP Accounts Receivable).

Regular business hours will resume at 9:00 a.m. EST on Friday, Jan. 2, 2026. - We’re retiring the File Exchange at the end of this year. The JMP Marketplace is now your destination for add-ins and extensions.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- DOE

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

DOE

Hi,

I have an interesting situation (at least to me) for a DOE. I need to design an experiment with 13 variables. Variable X1 and X2 (both numeric) cannot be in the experiment at the same time. If X2 is selected then the X2*X3 <= 1200. Furthermore, the ratio of X6 to X5 must be a whole number.

The goal of the experiment is to improve wafer uniformity as measured by etch depth across the diameter of the wafer.

No other constraints on the other variables (all numeric).

What would be the best design for this situation?

Thanks,

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

Hi @MarkovVaribles1,

I'm sorry but I can't understand some of the constraints :

- "If X13 is chosen, none of the X14, X15, and X16 can be selected." : What do you mean by "chosen" and "not selected" ? All the factors mentioned here have low levels different from 0 in your design, so I don't understand how to "choose" and "not select" some of the factors. Are these factors linked to each others (like mixture factors with constraints) ?

- "Further X14*X15 <= 1200" : Since the low levels for these factors are respectively 50 and 400 (50x400 = 20000), I don't see how to take into account this constraint... Either there is a problem in the factor levels or in the maximum value constraint.

- "Finally X13/X10 must be whole number." : Are you interested in individual factors X13 and X10 or only on their ratio/relative values ? If it's the second option, as mentioned in my previous answers, you can perhaps include only one factor X13/X10 instead of two individuals factors.

Looking forward to having more information,

"It is not unusual for a well-designed experiment to analyze itself" (Box, Hunter and Hunter)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

I don't want to get in the middle of this so I'll keep my thoughts brief.

1. You are trying to figure out what factors affect within wafer variation by measuring etch depth. Have you assessed the measurement system? Have you sampled to determine the within wafer etch depth is the most significant component? Is the within etch depth consistent across wafers? Are there any systematic patterns to the etch depth variation within wafer? Have you identified ALL factors that could possibly impact etch depth variability (some may be manageable, some not)? These questions should be answered before experimentation.

2. Assuming you have those answers, it appears you are screening. This is the first of a set of experiment iterations. Do not try to get everything out of the first experiment (it is extremely inefficient). Set it up so you have a clear path for the next experiment (do this by creating a rather large design space). For example, why don't you have a factor (power supply) and select settings on each power to maximize the differences that the power supply would have (bold but reasonable). I assume you think the power supplies are varying their power output WITHIN WAFER (Why?)? If power supply is interesting, then fine tune in a later experiment.

3. The constraints are confusing, it seems to me you just need to dial in some level setting. Remember BOLD but REASONABLE. You are not trying to pick a winner, you are trying to create significant enough variation to be able to assign it confidently to the subset of factors that are important. Next iterations will allow for more precise level setting and predictive modeling.

4. Lastly, make sure your response variable is for the variation within wafer, not the average etch depth (you will likely need repeated measures to get that estimate of variation).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

Hi!

Maybe you could add your overall objective ...

Cheers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

Hi @MarkovVaribles1,

As noted by @fja, providing more information and context can help other users guide you or giving you some advices.

Here are some based on what I may have understood from your topic :

- Since you have a quite high number of factors (13), I guess your primary objective would be to sort out significant from non-significant factors ? In this case, a D-optimal design (in the menu "Custom Design") could help you design a DoE that match your expectations (screening main effects of the input factors).

Concerning your specific cases for some factors :

- "Variable X1 and X2 (both numeric) cannot be in the experiment at the same time" : I see two potential solutions (to be tested/confirmed) : you could either use a "Disallowed combinations filter" in your DoE if low levels for these factors are at 0, or more simply create a categorical column "choice" with two levels (X1, X2) and a continuous column for the quantity/number of this variable to be tested. This should naturally respect your constraint of having only one of the variables in the experiment (X1 OR X2).

- "If X2 is selected then the X2*X3 <= 1200" : This may be a good case for using "Disallowed combinations filter", with the creation of a formula column X2*X3 in order to create the constraints. Or the use of covariates/candidate set may also be an alternative, in order to let JMP "pick" the most informative experiments from an "authorized" set of experiments datatable.

- "Furthermore, the ratio of X6 to X5 must be a whole number" : For this case, why not creating directly a factor X6/X5 if you are more interested in the ratio value than in the concrete numeric values from X5 and X6 ? With a screening design, you could set up low and high levels so that this ratio factor could only be a whole number, for example with a low level set at 1 and high level set at 2, 3 or 4...

These are my thoughts at the moment, some may be inaccurate or irrelevant depending on the missing context/objectives, but I hope some will help you in your design creation.

"It is not unusual for a well-designed experiment to analyze itself" (Box, Hunter and Hunter)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

Hi Victor,

Your suggested solution is much appreciated and I thank you for taking your time to help here. Only thing is with the ratio of the two factors being an integer. The two factors are Low Frequency and High Frequency of the power, both of which need to be specified for the experiment within certain operational range.

Thanks again!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

I tried to create the design and I get error messages!

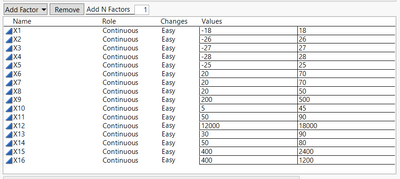

Here is the actual list of variables below.

Constraints: either if X13 is chosen, none of the X14, X15, and X16 can be selected. X14, X15, and X16 must be together in which case X13 is out. Further X14*X15 <= 1200. Finally X13/X10 must be whole number.

The goal of the DOE is to minimize variation of response across wafer (maximize uniformity).

Thank you for your time!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

Hello Markov!

I am a bit confused now. You have marked this thread as solved but still describe errors/problems you encounter. Are you settled?

--Fja

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

Hi,

Sorry, that was by mistake. I did post my last question and was waiting for a reply!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

Hi @MarkovVaribles1,

I'm sorry but I can't understand some of the constraints :

- "If X13 is chosen, none of the X14, X15, and X16 can be selected." : What do you mean by "chosen" and "not selected" ? All the factors mentioned here have low levels different from 0 in your design, so I don't understand how to "choose" and "not select" some of the factors. Are these factors linked to each others (like mixture factors with constraints) ?

- "Further X14*X15 <= 1200" : Since the low levels for these factors are respectively 50 and 400 (50x400 = 20000), I don't see how to take into account this constraint... Either there is a problem in the factor levels or in the maximum value constraint.

- "Finally X13/X10 must be whole number." : Are you interested in individual factors X13 and X10 or only on their ratio/relative values ? If it's the second option, as mentioned in my previous answers, you can perhaps include only one factor X13/X10 instead of two individuals factors.

Looking forward to having more information,

"It is not unusual for a well-designed experiment to analyze itself" (Box, Hunter and Hunter)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

Hi Victor,

Sorry I am not clear, so I try to explain differently.

1. If X13 is chosen, none of the X14, X15, and X16 can be selected: what I meant here is that the engineer has two power supplies: one associated with X13 and the other one with X14, X15 and X16. He can only choose one power supply per experiment. If he chooses power supply 1, then he only has X13, all other variables in place (excluding X13, X14, X15). If he chooses power supply 2 then X14, X15 and X16 come into play and X13 is no longer a variable.

2. "Further X14*X15 <= 1200": I should have mentioned that X14 is in percentage ... my apologies

3. "Finally X13/X10 must be whole number": here the interest is in the X13 and X10, and the engineer is requesting that we design the experiment keeping this in mind, so both of them need to be in the design.

In regards to item 1, I thought maybe one approach is just having two designs, one for each power supply. This may not be the best design and the reason I am seeking advice.

Thanks again for your time

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE

I don't want to get in the middle of this so I'll keep my thoughts brief.

1. You are trying to figure out what factors affect within wafer variation by measuring etch depth. Have you assessed the measurement system? Have you sampled to determine the within wafer etch depth is the most significant component? Is the within etch depth consistent across wafers? Are there any systematic patterns to the etch depth variation within wafer? Have you identified ALL factors that could possibly impact etch depth variability (some may be manageable, some not)? These questions should be answered before experimentation.

2. Assuming you have those answers, it appears you are screening. This is the first of a set of experiment iterations. Do not try to get everything out of the first experiment (it is extremely inefficient). Set it up so you have a clear path for the next experiment (do this by creating a rather large design space). For example, why don't you have a factor (power supply) and select settings on each power to maximize the differences that the power supply would have (bold but reasonable). I assume you think the power supplies are varying their power output WITHIN WAFER (Why?)? If power supply is interesting, then fine tune in a later experiment.

3. The constraints are confusing, it seems to me you just need to dial in some level setting. Remember BOLD but REASONABLE. You are not trying to pick a winner, you are trying to create significant enough variation to be able to assign it confidently to the subset of factors that are important. Next iterations will allow for more precise level setting and predictive modeling.

4. Lastly, make sure your response variable is for the variation within wafer, not the average etch depth (you will likely need repeated measures to get that estimate of variation).

Recommended Articles

- © 2025 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us