- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: Which Control Chart to use?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

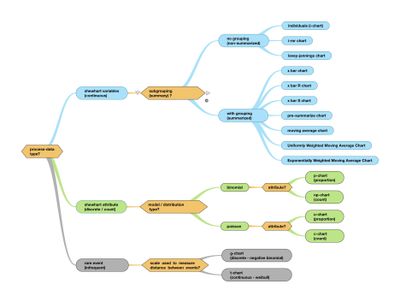

Which Control Chart to use?

Just joined the community today and had a question about control charts. I am collecting data that consists of 120 measurements taken once a minute. My goal is to understand the variation between the measurements (between 1 and 2, 2 and 3, etc.) and I have the measurements in groups for each minute of time (120 measurements for 12:01, 120 measurements for 12:02, 120 measurements for 12:03, etc.). Based on what I am trying to understand and the way in which the data is collected, which control chart would be best to use? I tried searching a few discussions on this, but was still confused whether my data is continuous or is actually divided into sub groups.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Which Control Chart to use?

"Dude" - I am not hating on anything. I just know what Six-Sigma is and is not. I used to be Technical Director at a large paper mill in Ohio, where I was in charge of the 6-Sigma program. The mill had six "certified" black belts. Of the six, only one had a clue what she was doing. As a result, she eventually landed a very nice job with a large chemical company. Here's part of a conversation I once had with one of the other "black belts". Me: "So, tell me, what is the p-value really telling me?" "Black Belt": I don't really know, but it is supposed to be less than 0.05 for the results to be real." Real? Are you kidding me? Six-Sigma actually brings nothing new to industry; it is a toolbox of methodologies that have been around for a long time, accompanied by a "recipe" to follow (DMAIC). There is nothing fundamentally wrong with that, but there are far too many companies cranking out so called "Black Belts" who are nothing but robotic recipe followers who really don't understand what they are doing. anything that does not fit the recipe, and they are lost. In fact, I have seen ads in trade journals that promise certification in as little as three weeks! That said, I also know some very talented folks who are certified Black Belts (including Master BB's), BUT their real expertise came not from Six-Sigma training, but from years of statistical study and practice.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Which Control Chart to use?

HI everyone.

This is what I gathered from the control chart types documentation.

* My understanding of the control chart process based on the documentation may be wrong, please correct it.

- Randy, JMP newbie

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Which Control Chart to use?

Randolph,

With proper rational sub-groups, you will be able to effectively utilize the Individuals/Moving Range chart about 95% of the time. Most of the other types of charts assume/require a certain distribution of the data in order to be effective. For example, the C Chart requires the Poisson distribution. Dr. Donald Wheeler has published a great deal on this subject that I suggest you read. Much of this can be found at QualityDigest.com. Just do a search of Wheeler's content on the site.

Best regards,

Steve

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Which Control Chart to use?

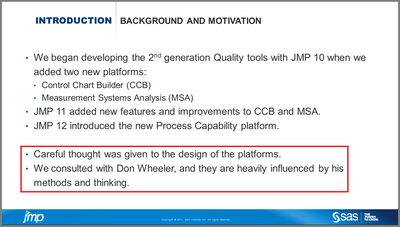

Thanks for the tips, Steve.

I will definitely search the archives of Quality Digest on Dr. Wheeler and control charts.

And in doing so, I hope to understand how the Control Chart Builder is influenced by the methods and thinking of Dr. Wheeler - as indicated in the deck below from the article An Integrated Process Improvement Approach Using the Second-Generation Quality Tools in JMP® posted 3 months ago.

Much appreciated.

- Randy, JMP newbie

- « Previous

- Next »

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us