- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: Representing 5 signals into 1: What's the best way to approach this in JMP?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Representing 5 signals into 1: What's the best way to approach this in JMP?

Hi,

My process has 5 temperature instruments at each height around the unit/equipment, measuring the temperature at the same level just at a slightly different location along the circumference.

So in total, across different heights we have close to ~50 temperature signals and looking at this is a headache because though the signals reads close to each other, it's difficult to detect any issues as typically only 1-2 signals that shows some signs on each level.

My question is that, what can I use in JMP Pro 17 to help simplify these 5 signals into 1 combined representative signal. I'd like to learn more on this modelling type.

Thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Representing 5 signals into 1: What's the best way to approach this in JMP?

Looking forward to answers from others, but meanwhile, can you explain how the 1 or 2 signals are different from the others? Maybe leading or lagging behind the average, or trending in a different direction, or perhaps off by a constant value? Is each height a different temperature? Is the interesting effect noticed within a height or between two or more heights or just amongst all 50 sensors?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Representing 5 signals into 1: What's the best way to approach this in JMP?

My suggestion is 'begin with the end in mind.' Is your study analytic or enumerative? Are you interested in monitoring the performance of the system or predicting future performance? What is the output of the system under study? What characteristics of the output are needed for deciding fitness for use? Do you know the variation of the measurement system itself?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Representing 5 signals into 1: What's the best way to approach this in JMP?

You might find this technique useful to answer the 'is something going on with my equipment?' question:

https://www.jmp.com/support/help/en/17.0/index.shtml#page/jmp/model-driven-multivariate-control-char...

But, it depends on what you want to learn/detect.

Signed,

Guy that monitors polymerization reactors...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Representing 5 signals into 1: What's the best way to approach this in JMP?

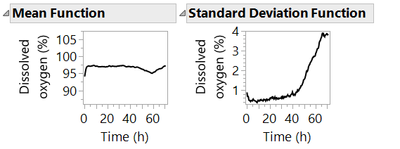

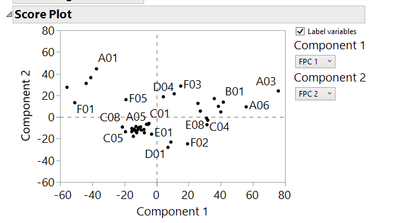

Are you monitoring the signals over time? Why not think about using the Functional Data Explorer? You could put in each signal (separated by an ID for position) for each hight and find out the mean and standard deviation trend over time (see plot below, this will point out where you're having the largest deviation from the mean) - then if any of your signals are deviating from the mean you can then isolate them with the Functional Principal Component Analysis (in this case 'sensor' A01 is behaving differently to the rest so may prompt investigation). Then you could produce a functional profiler that measures the signal pattern for each height.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Representing 5 signals into 1: What's the best way to approach this in JMP?

My response is more in line with Pete's:

Why do you care about the temperature readings? What response variables might they be affecting? Do you have hypotheses? Without knowing the complete situation, it is virtually impossible to provide specific advice.

Hypothetical:

Let's say this is a batch reactor and these sensors are providing readings of the temperature at systematic points around the reactor. The temperatures affect the concentration of the end product which is of utmost concern. Do you care about within reactor/batch variation? Are you concerned with stratification of the temperatures in the reactor/batch? Do you care about consistency of temperatures within batch? How about batch-to-batch? I would plot the data and compare the components of variation exposed by the different temperature readings. Get clues about the causal relationships between the temperatures and the end product.

Seems to me you might not want to combine the data into one metric until you understand what information that data may be providing. Summarizing the data throws out information.

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us