- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: Incorporating measurement error into Dunnetts analysis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Incorporating measurement error into Dunnetts analysis

I want to start incorporating my measurement error into my dunnetts analysis. I have attached a file below which has two variables which I am trying to determine if they are different. Both variables were tested 3 times and each test was measured 3 times. Since I am trying to determine if the variables are different in the past I've always just averaged all 3 measurements and used as the value for each test in my dunnetts analysis. However I was interested in finding out if there was a way to incorporate the error in my measurements into my analysis. Also, I was hoping for instructions on how to do this for myself since I will be doing this kind of analysis frequently in the future. Thank you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Incorporating measurement error into Dunnetts analysis

Not sure whether I understand you right,

but if you take the raw data for your analysis, you will see the error right in the result of the analysis. So I would take the raw data.

The analysis tells you, if the error is large in comparison to the difference between variables you want to detect.

But of course you need to care about the measurement, it needs to be precise enough to detect the difference you need to detect.

That's the reason, why you might need to do a MSA before starting real measurements.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Incorporating measurement error into Dunnetts analysis

Hi Georg,

Sorry for the delayed reply. You mentioned doing an MSA. What is that? I haven't heard that term before.

What you have suggested is one of the ways I've tried to do this analysis. But the issue I have is that it gives my experiment more power than it actually has. My experiment is looking at whether or not the variables are different. To do determine if this is true I have done 3 tests. So my n=3 for each variable. But if I take all of the measurement values JMP is analyzing the data like my n=9 which it does not. I unfortunately cannot fix the inherent error in my measurements. Looking at it from this perspective is it possible to use all of my measurement points and then manually change the n variable?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Incorporating measurement error into Dunnetts analysis

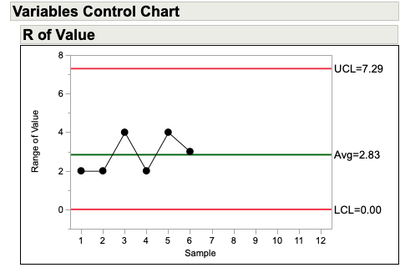

Here are some of my thoughts regarding your situation, realizing you haven't provided enough detail to be a sure. I don't know what a "test" is? Your study is crossed, nested. Meaning test and Variable are crossed and measurements are nested within those. Since you have multiple measures for each test, your measurement precision repeatability is confounded with within test variation. First you would want to determine if your measurement repeatability is consistent. This can be accomplished using range charts. Also , using the range chart can give you an idea about measurement system discrimination (also known as effective resolution). The guidance is to have at least 5 measurement units inside the upper control limit of the range chart. Your example is near the limit of acceptability.

If the precision repeatability is consistent and has sufficient discrimination, you can them average those values to reduce the error.

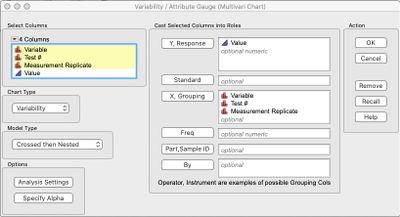

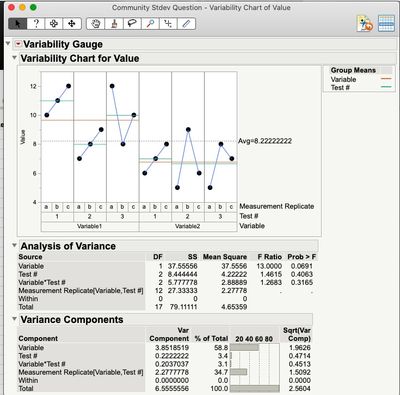

If you prefer a quantitative approach, you can get variance components for your study (Analyze>Quality and Process>Variability/Attribute Gauge Chart). Put the Y in the Y, Response box and the layers of your sampling tree starting with Variable/Test/Measurement. Select crossed then nested in the Model Type.

Using the red triangle nest to Variability Gauge, select Variance Components.

MSA and MSE are acronyms for Measurement System Analysis or Evaluation (See also EMP). These acronyms are typically associated with the work of Wheeler and are a recommended alternative to the traditional gauge R&R study. See here:

https://www.jmp.com/en_us/whitepapers/jmp/emp-management-systems-analysis.html

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Incorporating measurement error into Dunnetts analysis

Thanks for the reply Statman. I will start trying to do some statistical analysis of my values. But it looks like I might want to look into cleaning up the variability in my values.

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us