- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- How to deal with experimental disallowed space in DoE

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

How to deal with experimental disallowed space in DoE

Probably not the best title but here goes....If I was wanting to do a DoE screening design followed by optimisation study with a number of factors relating to a chemical reaction, how could I handle temperature, if the setpoint is at the solvent boiling point? Under this circumstance a lower (-1) value is available but studying a higher value (+1) is experimentally challenging. Lowering the setpoint for the study so that ±1 values are experimentally feasible could be one option. Is there another or a better way?

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to deal with experimental disallowed space in DoE

Hi @kjwx109prime,

Indeed, lowering the setpoint for the study so that all maximum values (coded +1) are feasible in the project could be an idea, but depending on the selected solvants used and their boiling points differences, some large experimental area between the maximum value of the design +1 and the boiling points of each solvant may not be explored.

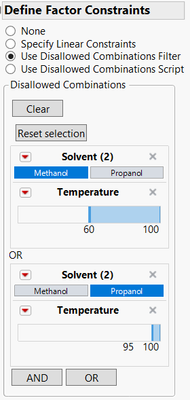

A more practical and flexible way to deal with these differences could be to use the disallowed combinations filter in the Custom Design platform. Here is a small DoE as an example, dealing with 2 factors :

- A categorical 2-levels factor, the choice of solvent : Methanol or Propanol.

- A continuous factor, Temperature (°C).

As the boiling point of Methanol is around 65°C and the one of Propanol is around 97°C, I want to define disallowed combinations in my experimental plan : no experiments should be run above 60°C when using Methanol, and no experiments should be run above 95°C when using Propanol. I can define this constraint using "Disallowed Combinations Filter" :

Or using the following script in the "Disallowed Combinations Filter script" :

Solvent == "Methanol" & Temperature >= 60 | Solvent == "Propanol" & Temperature >=

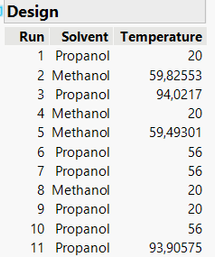

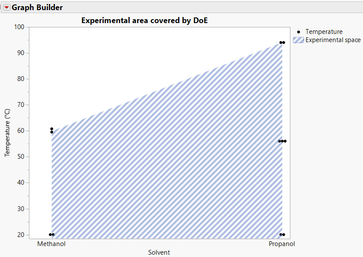

95After specifying my model, I can check than my experimental constraint has been considered in my design :

I can highly recommend reading the blog post by @Jed_Campbell who clearly explains the use of constraint and how to set them up in DoE : Demystifying Factor Constraints

Attached you will find the datatable used for this example to check the construction of the constraint and resulting design.

I hope this answer will help you,

"It is not unusual for a well-designed experiment to analyze itself" (Box, Hunter and Hunter)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to deal with experimental disallowed space in DoE

Hi @kjwx109prime,

Indeed, lowering the setpoint for the study so that all maximum values (coded +1) are feasible in the project could be an idea, but depending on the selected solvants used and their boiling points differences, some large experimental area between the maximum value of the design +1 and the boiling points of each solvant may not be explored.

A more practical and flexible way to deal with these differences could be to use the disallowed combinations filter in the Custom Design platform. Here is a small DoE as an example, dealing with 2 factors :

- A categorical 2-levels factor, the choice of solvent : Methanol or Propanol.

- A continuous factor, Temperature (°C).

As the boiling point of Methanol is around 65°C and the one of Propanol is around 97°C, I want to define disallowed combinations in my experimental plan : no experiments should be run above 60°C when using Methanol, and no experiments should be run above 95°C when using Propanol. I can define this constraint using "Disallowed Combinations Filter" :

Or using the following script in the "Disallowed Combinations Filter script" :

Solvent == "Methanol" & Temperature >= 60 | Solvent == "Propanol" & Temperature >=

95After specifying my model, I can check than my experimental constraint has been considered in my design :

I can highly recommend reading the blog post by @Jed_Campbell who clearly explains the use of constraint and how to set them up in DoE : Demystifying Factor Constraints

Attached you will find the datatable used for this example to check the construction of the constraint and resulting design.

I hope this answer will help you,

"It is not unusual for a well-designed experiment to analyze itself" (Box, Hunter and Hunter)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to deal with experimental disallowed space in DoE

I don't know the situation well enough to provide specific advice, but here are my thoughts.

There are options as Victor points out, but something to keep in mind, you are developing the "optimal" model in your first experiment. You are trying, in a relatively short time period, to determine which of the factors in your study should be studied further (This is the intent of screening. It is not to pick the winner). The problem with restricting the time period is that restriction narrows the inference space dramatically. To compensate for this narrow inference space, you do things to exaggerate the potential effects in your study. This induces another negative side effect which is bias. So you try and exaggerate everything in the experiment "equally" to compensate for the bias. For example, ALL factors tested at bold but reasonable levels, those levels are balanced across factors, Noise exaggerated and perhaps assigned in blocks. Point being, you want to find out the effect of temperature compared to the other factors and noise in the study with a fair comparison. Is the effect worthy of further study and optimization?

Now, to be clear, domain knowledge might indicate temperature matters and you eventually want to know what is the best temperature to achieve the required response variables. Perhaps this is best studied sequentially? Or via sampling? BTW, is this a mixture of chemistries?

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us