- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: 2 Mixtures Design Question

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

2 Mixtures Design Question

Hello, I am very new to JMP and I'm trying to design an experiment with 2 mixtures and a couple of other non-mixture variables each with 3 factors in JMP 16 Pro.

Mixture A is produced first in batches. Each batch of mixture A is then divided into five parts where I then add varying amounts mixture B. Is there way to do this in JMP?

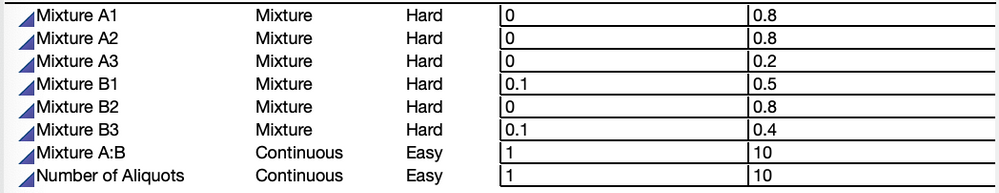

Here is what I have so far in my experiment:

Thanks.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: 2 Mixtures Design Question

Sorry, It is difficult to provide much specificity in which experiments to run when adequate context is not provided. I can completely understand the situation may be confidential, and that may not allow you to provide details. Unfortunately, without some essential criteria for design selection, it is difficult to provide advice. For example, we don't know what effects you are trying to estimate (do you have a model in mind?).

That doesn't mean you don't have options. For example, instead of doing a classic mixture design, you could think about combining factors into ratios and then exaggerate those levels and run a screening design with the other factors.

You could still do a split-plot design as the processing is sequential. Design and run an experiment to create batches. Then run a second experiment on the samples from those batches.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: 2 Mixtures Design Question

Welcome to the community. Is this the first iteration for understanding the causal relationships, or have you already done screening? Mixture designs are optimization designs for the most part. If I understand your situation correctly, you have a split-plot mixture design (First mixture design makes the whole plot, second mixture design is the sub plot). Are there any constraints? How many levels do you want to test? Why does the batch need to be divided into 5 parts? There are many options for Mixtures: Optimal, Extreme vertices, Simplex, etc. You might start here:

https://www.jmp.com/support/help/en/17.0/?os=mac&source=application#page/jmp/mixture-designs.shtml

There are also other platforms way to do this (Custom Design), not necessarily easy for a JMP novice.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: 2 Mixtures Design Question

Thanks for replying! This is meant to be a screening design for my experiment. I am using a Custom Design since there are non-mixture variables and each non-mixture variable will have 2 levels. Since materials for mixture A takes a good amount of effort I make them in batches. I figured that dividing each mixture into 5 will give me enough sample to test. With the split mixture plot design, I am unable JMP software to treat these 2 mixtures as separate mixtures. When I assign role to 1 one mixture factor from "Hard" to "Very Hard" the software disallow me from doing so since the software thinks of both mixtures as one.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: 2 Mixtures Design Question

Sorry, It is difficult to provide much specificity in which experiments to run when adequate context is not provided. I can completely understand the situation may be confidential, and that may not allow you to provide details. Unfortunately, without some essential criteria for design selection, it is difficult to provide advice. For example, we don't know what effects you are trying to estimate (do you have a model in mind?).

That doesn't mean you don't have options. For example, instead of doing a classic mixture design, you could think about combining factors into ratios and then exaggerate those levels and run a screening design with the other factors.

You could still do a split-plot design as the processing is sequential. Design and run an experiment to create batches. Then run a second experiment on the samples from those batches.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: 2 Mixtures Design Question

Thanks for the answer! Actually I can give a bit more information with what I am working with. The first mixture is used to make a nanoparticle formulation. The second mixture is a solution of liquids where I hydrolyze the liquid chemical compound, B1. I am interested in the effects of the hydrolyzed compound, B1, in how it interacts with the nanoparticle solution. B2 and B3 are chemicals that affect the hydrolysis rate of B1. I am interested in the interaction between hydrolyzed B1 and the nanoparticles.

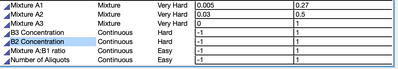

Since I am more interested concentrations / amount of B1 is it possible to run these factors as continuous? Here is what I am thinking in regards to the factors:

**ignore the upper and lower values**

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: 2 Mixtures Design Question

Do you have any individuals with DOE expertise or experience in your company? My suggestion is to develop multiple plans, evaluating each for what effects can be estimated, ease of execution, what isn't in the study, resource requirements. Then predict ALL possible outcomes from each potential plan. Compare potential for knowledge gained vs. cost to gain knowledge. Then pick one and run it.

I don't know if you tried searching on previous posts/threads. For example:

Although not directly comparable, there are a number of references in that thread that would be good to read.

For your scenario (again I still don't know all of the variables in the process), is it possible to run an experiment on the factors you think might affect the nanoparticle formulation and create multiple "batches" of the nanoparticle formulation (also don't understand why this can't be measured (e.g., particle size, distribution of particles, chemical composition, etc.))? Then, for each batch made from the first experiment, split those batches into smaller samples and run the second experiment on each of those samples (the number of samples would be dependent on the number of treatments in the subplot experiment). This would give you the whole plot for the first experiment and the subplot of the second experiment. Also you would be able to assess the interactions between the whole plot factors and the subplot factors. So it is essentially 2 experiments merged together and executed sequentially.

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us