The clock project is still moving forward. It needs a case of some sort. This is not the final case design, but the JSL to save the SVG pattern to send off to the laser cutter is a good start.

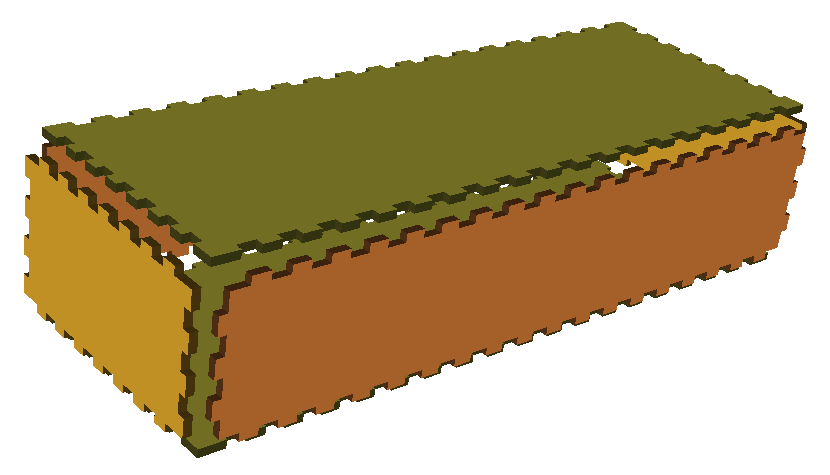

The JSL has an Explode parameter to help see how the sides slide into place.

The JSL has an Explode parameter to help see how the sides slide into place.

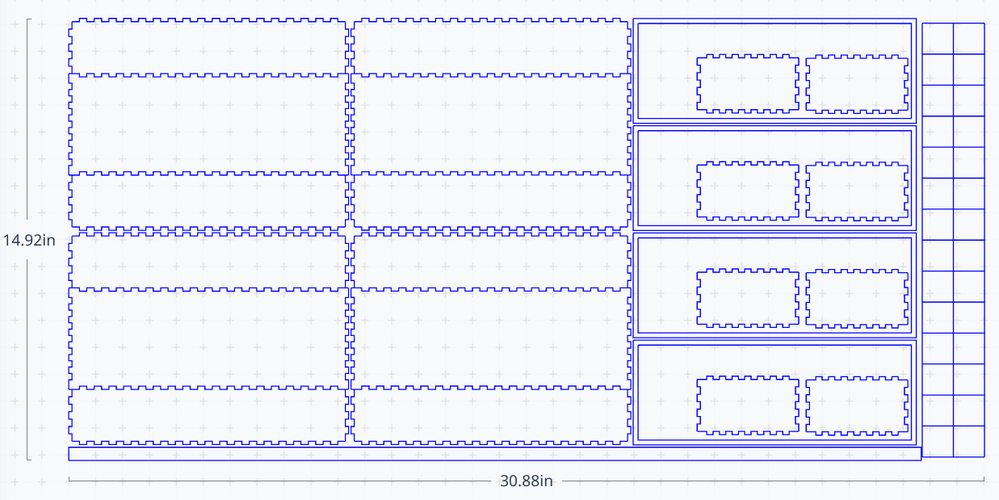

The SVG output needs to be hand optimized; here's a test I did with Ponoko, grouping the parts to make four cases on the 15x31 material.

Trial arrangement. Use Inkscape to move and copy the outlines.

Trial arrangement. Use Inkscape to move and copy the outlines.

You can find online generators like Maker Case too. But I'm already thinking about a variation.

JSL attached, below.