Screening and Controlling Manufacturing Processes

Published on

11-07-2024

03:28 PM

by

| Updated on

11-07-2024

05:38 PM

See how to:

- Use Process Stability and Process Screening to help control complicated manufacturing processes

- Screen processes for many (1000+) process variables over time to determine process stability

- Import multiple files and format for process analysis

- Screen for outliers by quartile range and handle outliers as appropriate

- Save outlier cleanup script for future use

- Screen for missing values

- Use Process Screening Control Chart to examine quality trends

- Interpret Stability Index to locate less stable subgroups

- Identify questionable areas and run Individual Moving Range Charts to examine and identify possible cause of variation

- Determine process capability

- Interpret 4-quadrant Process Performance Plot to compare and assess capability and stability combinations

- Drill into Control Charts for variable of interest

- Screen historical data to find variables most likely to impact your process

- Use Model-Driven Multivariate Control Charts to monitor parameters for multiple processes

- Interactively explore and understand the underlying components that lead to out-of-control signals

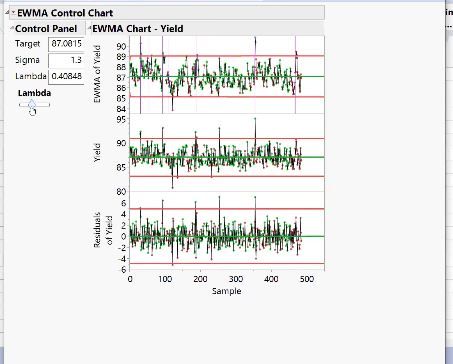

Note: Q&A is interspersed throughout the video beginning at time ~18:40. At time ~30:50, you can see the EWMA (Exponentially Weighted Moving Average) Chart which was updated in JMP 16 to include more interactivity and functionality. EWMA is useful to detect small shifts in a process.

Exponentially Weighted Moving Averagae Charts are useful for detecting small process shiftsExponentially Weighted Moving Averagae Charts are useful for detecting small process shifts

Exponentially Weighted Moving Averagae Charts are useful for detecting small process shiftsExponentially Weighted Moving Averagae Charts are useful for detecting small process shifts

Resources

- Blog with instructions for 3 capabilities added to Process Screening in JMP 16 (single-launch XBar and IMR charts; ability to color and select out of spec values. ability to alter KSigma to make alarm tests more or less sensitive)

Start:

Wed, Jul 29, 2020 02:00 PM EDT

End:

Wed, Jul 29, 2020 03:00 PM EDT