JMP Blog

A blog for anyone curious about data visualization, design of experiments, statistics, predictive modeling, and more- JMP User Community

- :

- Blogs

- :

- JMP Blog

- :

- 【案例研究】 | 應用智慧演算法預測寶鋼1580熱軋精軋自然寬展

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

智慧製造是股份公司在新形勢下技術發展的必然趨勢,也是在激烈的市場競爭中贏得主動、立於不敗的重要保證。1580 熱軋智慧車間建設是寶鋼第一個作為國家工信部試點的示範智慧化專案,通過引進和升級現有技術和裝備,寶鋼邁出了鋼鐵工業智慧化升級的步伐。

本文將詳細介紹寶鋼如何應用基於JMP Pro的智慧演算法,預測1580熱軋精軋的自然寬展的項目實踐,也是2020 JMP Discovery Summit China寶鋼股份設備部數模主任工程師朱健勤先生當天演講內容的補充。

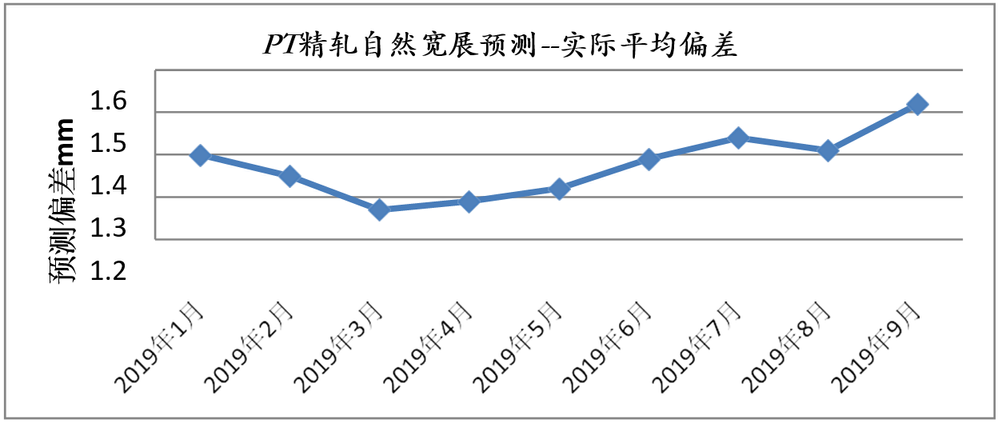

一 專案背景—為何需要JMP Pro?

寶鋼 1580 熱軋智慧車間建設工程中,精軋動態寬度控制(DWC)系統由德國普瑞特公司(Primetals Technologies Germany GmbH,簡稱 PT)將其精軋自然寬展預測及自我調整的神經網路模型嵌入到 L2 系統中,通過 L2 過程參數的輸入,計算精軋自然寬展的預測值,用於確定粗軋目標寬度及軋後自我調整,並作為參考值傳送至 L1,由 L1 實現精軋寬度的動態控制,從而顯著地提高了 1580 熱軋精軋出口寬度的控制精度,其模型預測值與實際值的平均偏差僅有 1.38mm(2019 年 1 月~9 月),參見圖 1。

圖1

然而,德國普瑞特公司提供的精軋自然寬展預測及自我調整神經網路模型是一個黑箱模型,其原始程式碼是經過加密的,無法閱讀或修改,也沒有模型結構說明,因而無法進行參數調整、模型調優等改進工作。

因此,團隊希望能夠通過應用JMP統計分析產品家族的其他機器學習、深度學習等人工智慧建模工具,開發出一個智慧模型,用於寶鋼股份1580熱軋廠的精軋自然寬展預測,籍以替代德國PT公司的黑箱模型,並使該自主開發模型的預測值與實際值的偏差達到月平均值≤1.7mm,從而基本達到德國黑箱模型的控制水準。

基於此,團隊開始借助於JMP Pro中的預測建模工具作進一步的嘗試和探索。

二 智慧化預測模型的建立

1 資料的收集與清理

團隊採集了 1580 熱軋 2019.01~2019.09 共九個月的精軋生產資料,並編制 SAS 程式對其中 2019 年 1~8 月的資料進行清理與整合,共提取出有效資料 85423 塊帶鋼,並匯總形成 Excel 資料檔案。

2 數據篩選

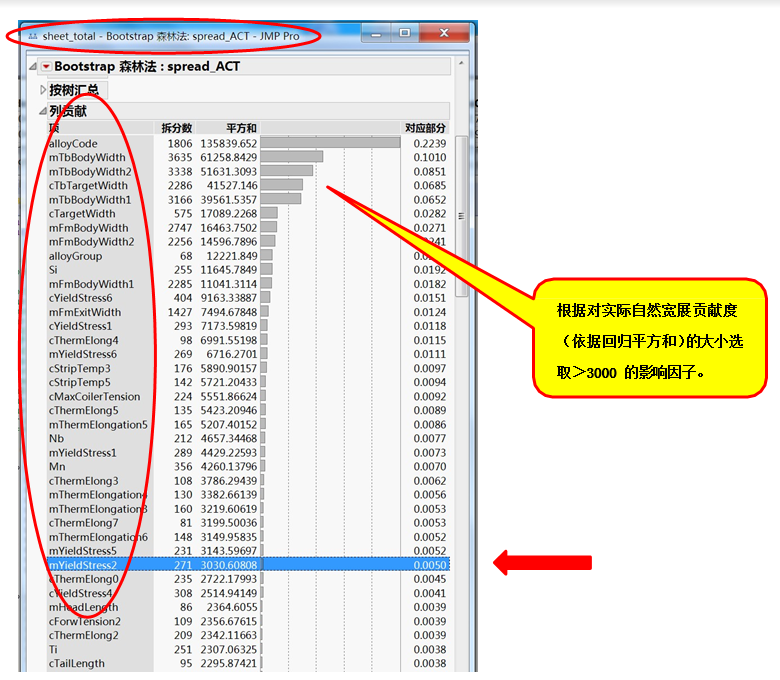

01 運用智慧演算法篩選關鍵因數

應用JMP Pro統計分析軟體中的 Bootstrap 森林演算法對該資料集(2019 年1~8 月,85423 條記錄、206 個影響因數)進行擬合訓練,然後從訓練的結果中根據對實際自然寬展貢獻度(依據回歸平方和)的大小,選取方差平方和>3000 的影響因數,共31 個,參見圖 2。

圖2

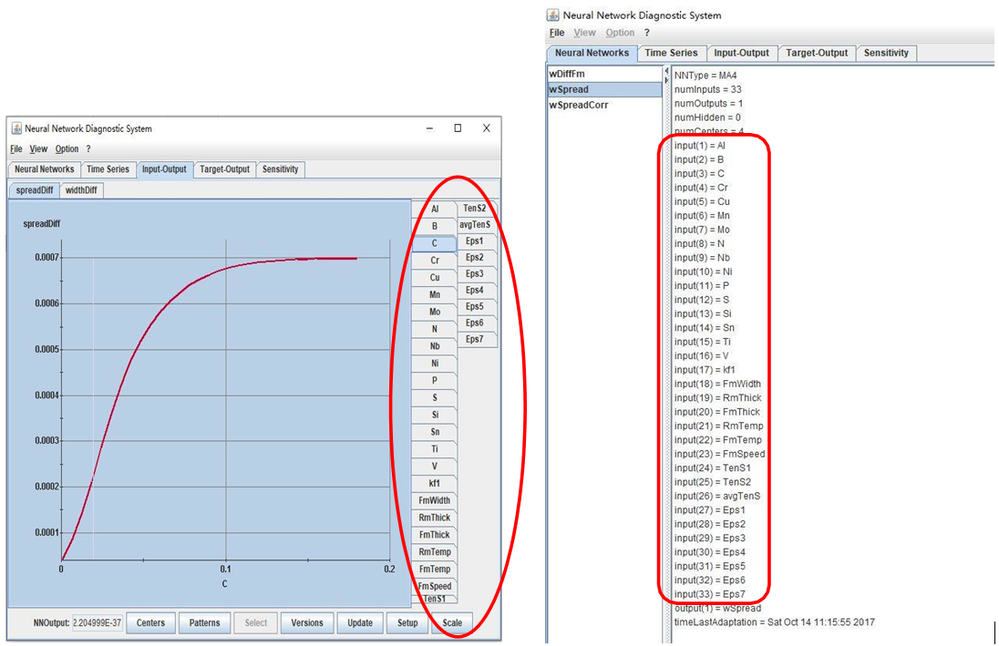

02 普瑞特(PT)公司經驗傳承

由德國普瑞特(PT)公司提供的自然寬展神經網路模型分析診斷系統的輸入/輸出介面,不難看出該神經網路黑箱模型需要化學成分、精軋入口寬度、出口寬度等 33 個輸入變數, 參見圖 3。

圖3

03 資料合成

團隊將 JMP Pro的Bootstrap森林演算法篩選的關鍵因數與普瑞特(PT)公司神經網路模型所需的輸入變數進行對比,可以發現有 4 個影響因數是相同的,它們是預計算的精軋目標寬度及化學成分矽(Si)、鈮(Nb)等。

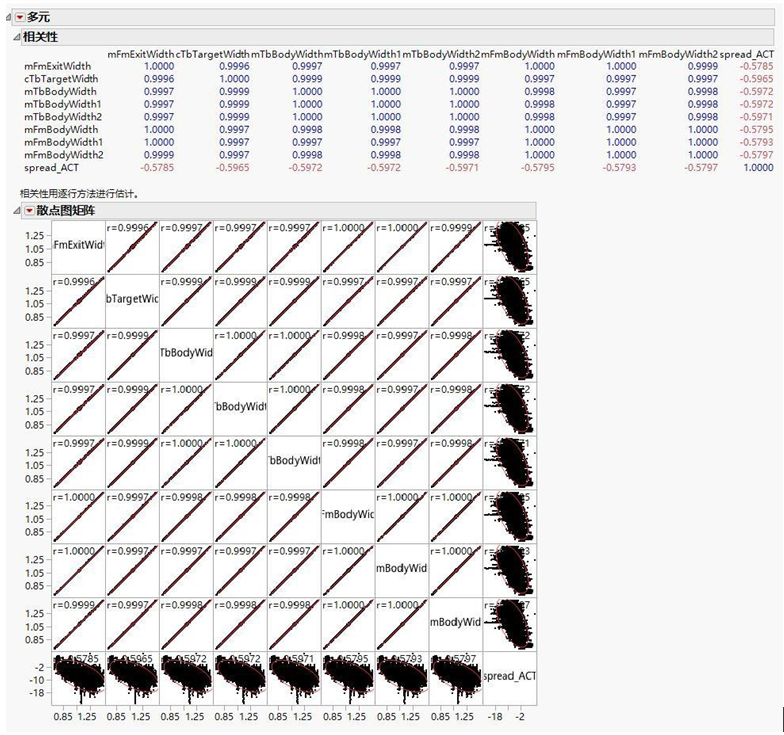

同時,根據生產品質分析經驗,不難看出粗軋實際寬度、粗軋後半寬度實際值、粗軋目標寬度等因數之間存在自相關性,並且這些變數與團隊需要擬合的目標實際自然寬展(spread_ACT)也存在線性相關性。應用JMP Pro 的多元線性相關性分析工具對這八個影響因數及自然寬展實際值進行分析,可以看到八個影響因數之間呈強相關關係(相關性係數 r>0.99),且與自然寬展實際值的相關性也比較強(r>55%)。參見圖 4。

圖4

除此以外,出鋼記號(alloyCode)有 1000 多個,雖然其對自然寬展有影響,且貢獻度最大,但由於維度太大,無法進行擬合,可以另行採用表格方式進行自我調整學習。

因而經過討論,最終決定將這 9 個變數刪去,加上重複的 4 個變數共刪去 13 個影響因數。這樣 31 個影響因數還剩餘 18 個,加上普瑞特公司經驗傳承的 33 個因數,最終確定 51 個影響因數。

3 數據準備

針對最終確定的影響精軋自然寬展的 51 個影響因數,團隊採集了 2019 年 6 月至 8 月共三個月的資料(共 30533 塊帶鋼),應用 JMP Pro讀取這些資料,並將精軋自然寬展實際值作為目標值(Y,回應變數),51 個影響因數作為擬合數據(X,引數),並隨機設置該擬合資料集的 80%作為訓練集,20%作為驗證集。

三 智慧模型的訓練及離線擬合

團隊嘗試應用 JMP Pro分析軟體中的兩種智慧建模方法:神經網路及 Bootstrap 森林法分別對上述資料集進行訓練和驗證,得到如下結果:

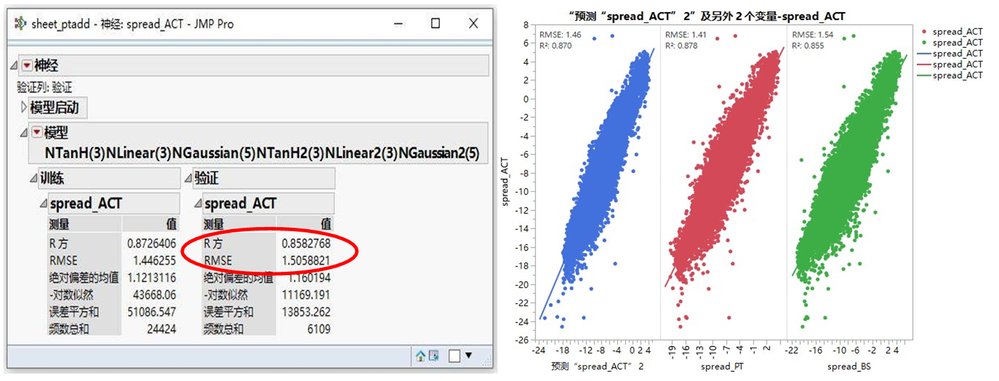

1 應用神經網路建模方法

圖5 圖6

由圖5和圖6可知,應用神經網路演算法訓練擬合後得到的模型,用驗證資料驗證後的決定係數 R2 為 0.858,RMSE 為 1.506,絕對偏差的平均值為 1.16,理論上已經達到了團隊設定的目標。

圖6給出了三種模型的預測值(從左至右依次是 JMP 模型、PT 模型及寶鋼現有模型)與實際值的散佈圖,從中可見 JMP 擬合的模型其離散程度是最小的。

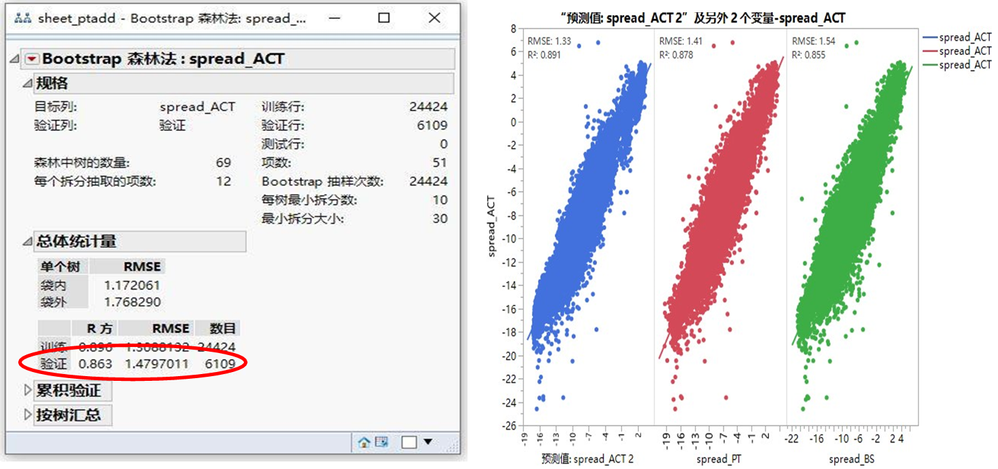

2 應用Bootstrap森林法建模方法

圖7 圖8

由圖7和圖8可知,應用 Bootstrap 森林法訓練擬合後得到的模型,用驗證資料驗證後的決定係數 R2達到了 0.863,RMSE 為 1.48,獲得了更高的預測精度。

同樣,圖8給出了三種模型的預測值(從左至右依次是 JMP 模型、PT 模型及寶鋼現有模型)與實際值的散佈圖,從中可見 JMP 擬合的模型其離散程度是最小的。)

由上述兩種智慧模型演算法的應用可以看出,Bootstrap 森林演算法的擬合效果比神經網路要好,預測精度更高,這兩種建模方法都達到了專案團隊的目標。

但是,這僅僅是對資料的理論分析結果,究竟實際應用效果如何,還是要用現場的實際控制資料來說話。如何將這些智慧演算法建立的模型應用於實際控制才是真正有意義的工作。

JMP Pro軟體的模型匯出功能為團隊架起了理論到實踐的橋樑,跨越了離線分析到線上應用的鴻溝,使得天塹變通途。

四 智慧模型的線上驗證

1 模型的匯出

應用JMP Pro 軟體將這兩種智慧模型演算法轉換成了 C 語言代碼,從而為智慧控制模型在現場的實際應用,跨出了關鍵性的一步。

2 模型的線上驗證

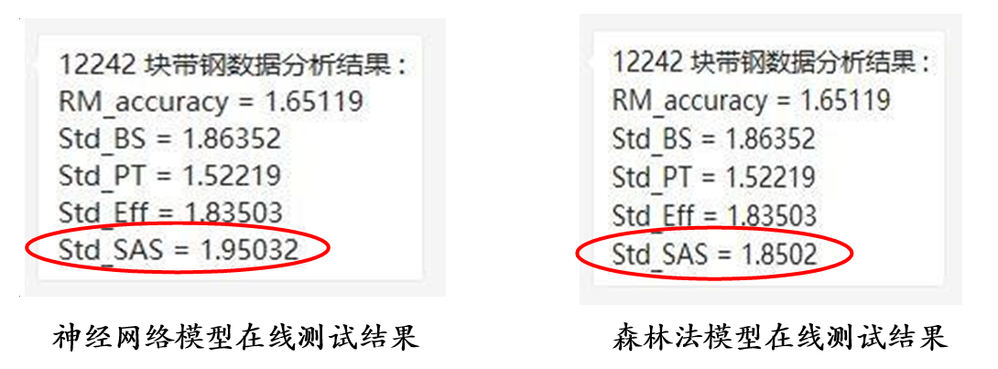

將兩種智慧模型演算法轉換成的 C 語言程式碼經過編譯後集成到 1580 熱軋粗軋過程電腦離線類比機的預設定進程中,然後應用 2019 年 9 月份的資料進行測試,即輸入因數是 9 月份的帶鋼實際資料,運用智慧模型預測精軋自然寬展,然後採用普瑞特 PT 公司相同的標準差計算公式分別計算寶鋼模型、PT 公司模型和 JMP智慧模型的標準差,參見下圖 9:

圖9

由圖 9 可見,從實際預測結果看,JMP 森林法擬合得到的模型,其預測結果已經達到了寶鋼現有模型的預測結果!

五 專案小結及經驗

通過運用JMP Pro統計分析軟體中的智慧分析及建模方法,團隊對 1580 熱軋精軋自然寬展的預測值、實際值以及相關參數進行了訓練、驗證和擬合,得到了神經網路和Bootstrap 森林兩種智慧控制模型,其理論預測精度和驗證精度完全達到了德國普瑞特公司的神經網路模型精度。

同時,借助於 JMP Pro軟體的模型發佈功能,團隊獲得了其 C 語言的程式碼,並在現場程式控制電腦的類比機上進行了預設定進程實際測試,取得了非常好的效果,從而為下一步開展線上生產試驗和驗證奠定了充實的基礎。

除此以外,在分析和建模過程中,團隊也總結了以下幾點經驗供大家參考:

- 訓練資料的時間跨度不宜過長,以 3~4 個月為宜;

- 訓練驗證的資料量不宜過大,以 3~4 萬條記錄為宜;

- 如果配以自我調整學習功能,可以使預測精度更高。

可以看到的是,隨著中國製造2025戰略的提出和推進,製造業逐步從製造向“智造”轉型與升級,智慧製造賦能未來鋼廠勢在必行。寶鋼1580熱軋精軋自然寬展項目的嘗試與探索,為寶鋼其他產品線的智慧製造之路提供了很好的參考和依據,科學的分析工具必將成為製造業走向詩和遠方不可或缺的強大引擎。

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.