- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Mixture DOE Constraints

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Mixture DOE Constraints

I am a new user for JMP, I am trying to create a design of experiment for a mixture. I have four factors in my experiment : resin, plasticizer, Modifier A, Modifier B. I do not want Modifier A to be in the same batch with Modifier B. I want Modifier A or Modifier B not both. How do I create a constraint to disallow these two ingredients to be together in the same run?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Mixture DOE Constraints

This is a really good example that Tom Donnelly wrote up a while back.

Tom Donnelly's Mixture Design DOE Slides and Case Study Descriptions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Mixture DOE Constraints

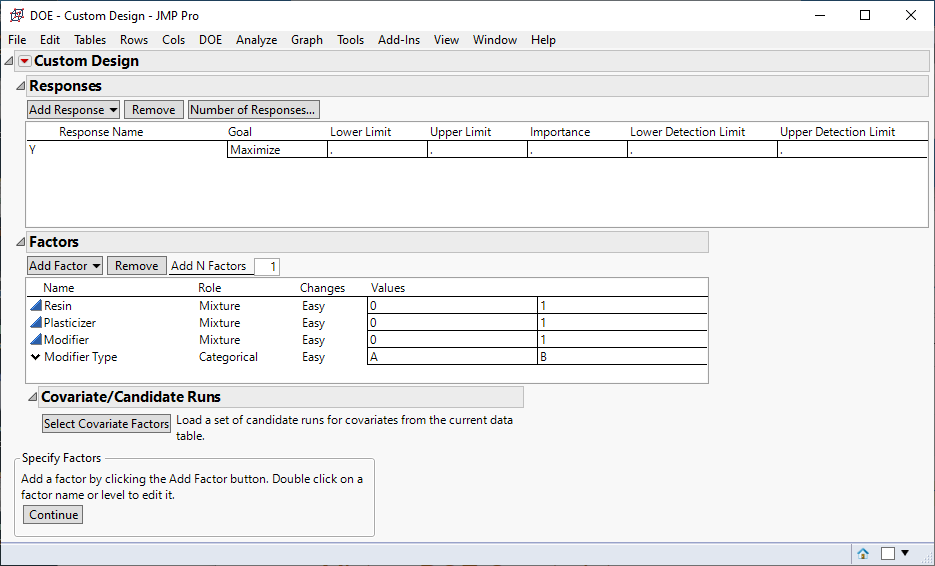

Here is a simple solution. Separate the proportion of the Modifier and the type of Modifier. Something like this:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Mixture DOE Constraints

I thought about doing this but Modifier A has a range of 0 to 0.09 and Modifier B has a different range of 0 to 0.3

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Mixture DOE Constraints

It would seem that it should be possible to set up the design as @Mark_Bailey suggests and then add

Modifier Type = A & Modifier > 0.09

as a disallowed combination.

However, you can't have disallowed combinations with Mixture factors in Custom Design :(.

I'm not sure why this is. I guess it is complex to implement constraints with optimal mixture designs. You might want to add that as a request in the JMP Wish List.

So I think you might need to use the Candidate Set Design approach as presented by @chris_gotwalt1 at JMP Discovery Europe 2021.

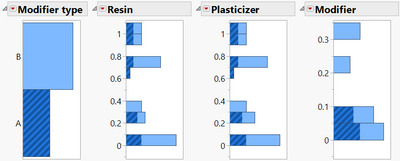

Following this approach I created a "Big Design" of 2000 runs that obeys the constraints that you have. Then used this as a candidate set for the smaller 40-run Custom Design. (Both designs attached). I think this approach would work for you?

You can see that it obeys the constraint you stated:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Mixture DOE Constraints

You could leave the default range -1 to +1 (coded levels) for Modifier. You can then interpret the results on the respective scales.

I generally advise against using a level of 0 for a continuous factor (mixture components are modelled as a continuous variable) because you essentially make it categorical (present, not present). I recommend using something close to 0, but far enough away to be meaningful. That advise, though, does not really apply to the proportion of a mixture component.

You are getting lots of ideas for solving your experiment design!

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us