- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: How to determine the Process Parameters operating window from a Design of Ex...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

How to determine the Process Parameters operating window from a Design of Experiment?

Hello JMP Community,

I work at a manufacturing facility as a Process Engineer.

I am trying to find some standard or guidance on how to determine the operating window of identified Process Parameters following a Design of Experiment in JMP?

Some background I performed a Design of Experiments and I analyzed the interactions and determined which Process Parameters (factors) were most significant with respect to my Product Characteristics (responses). I not only need to find the best running setting (target) to set my Process Parameters but also to find the operating window (lower and upper limit) to find the "cliff" where I will begin seeing defective product.

Example: I have three inputs Pressure (continuous), Angle (continuous), Heater (categorical). I have three outputs Pull Force (continuous), Pull Force Failure Mode (categorical), Length (continuous). I am attaching the DOE results for this example.

So far I have used the Monte Carlo simulation yet haven't found a straightforward way to determine the operating window.

Looking for some guidance and interested in an interactive explanation rather than scripting answer from this very knowledgeable community.

Thanks,

Jorge.

EDIT 11/29/17: Added desirability to the spreadsheet. Desirability: Pull Force = 1, Pull Force Failure Mode = 2, and Length = 1

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to determine the Process Parameters operating window from a Design of Experiment?

Not answering your question directly, but if you haven't, I would take a look at Robert Anderson's excellent Discovery paper. The 'simulation experiment' capability is a little hidden, but incredibly useful.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to determine the Process Parameters operating window from a Design of Experiment?

This might be a 'big' question, and I'm sure many will have an opinion.

But (at the risk of telling you what you already know), I took a quick look at the XLSX you supplied, and put it into a JMP table (attached). Looks like your design was a two-level full factorial in 'Pressure' and 'Angle', with two replicates at each corner and then also a single 'centrepoint' (not actually in the centre of the design space). This pattern was repeated for each 'Heater'. You might like to look at the 'Spec Limits' and 'Response Limits' column properties. These should be useful in answering your bigger question.

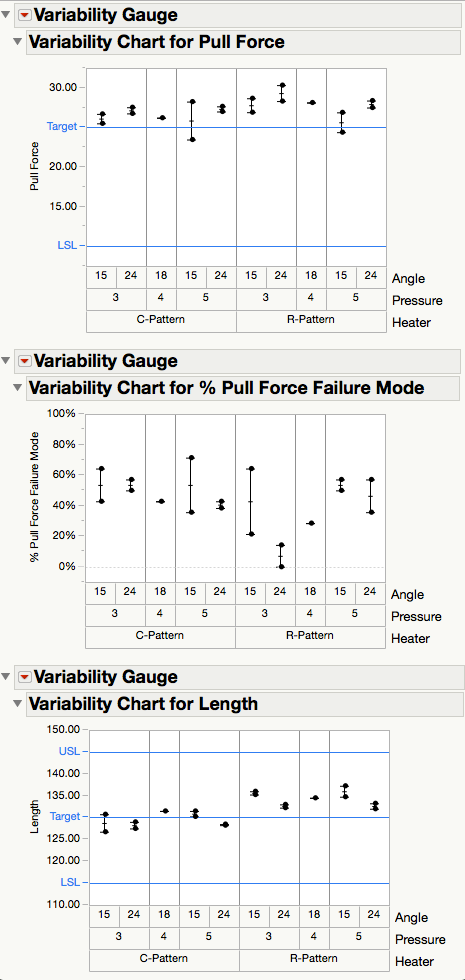

Using 'Analyze > Quality and Process > Variability / Attribute Gage Chart' I made:

You didn't say how important the three responses are relative to each other. But it seems that the 'Lengths' for 'R-pattern' are always above target (which is bad), but that settings of 3 and 24 for 'Pressure' and 'Angle' give rise to much lower values of '%Pull Force Failure Mode' (which is good).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to determine the Process Parameters operating window from a Design of Experiment?

Hello Ian, thanks for the response. I added the importance to the spreadsheet. I didn't think to use the Variability / Attribute Gage Chart. I typically use the Fit Model yet it's a good way to look at the data.

I know the centerpoint it's off but it wan't possible to do it in the machine while doing the runs. So I went with the closest possible setting.

I'm still in search of that good method to determine my operating window? I want to know the lowest and highest I can set my inputs (Pressure and Angle) before I'm outside of specification.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to determine the Process Parameters operating window from a Design of Experiment?

To pile onto my colleague Ian's input, JMP's contour profiler capability is tailor made for determining operating windows for factors. Here's a link to the JMP online documentation regarding the contour profiler capability:

http://www.jmp.com/support/help/13-2/Contour_Profiler_Overview.shtml

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to determine the Process Parameters operating window from a Design of Experiment?

Thank you Peter. I have been using the Contour Profiler to get an idea of an operating window. Do you have some more information on how to find an operating window using Contour Profiler? A step-by-step guide or an detailed explanation that someone published? Thanks in advance.

Jorge.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to determine the Process Parameters operating window from a Design of Experiment?

Not answering your question directly, but if you haven't, I would take a look at Robert Anderson's excellent Discovery paper. The 'simulation experiment' capability is a little hidden, but incredibly useful.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to determine the Process Parameters operating window from a Design of Experiment?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How to determine the Process Parameters operating window from a Design of Experiment?

Jorge:

There are an enormous amount of examples, case studies, webinars, etc. available on jmp.com. For webinars, I'd look in the Mastering JMP series. For something published...pretty much all the ideas myself and @ian_jmp have shared are very well explained by my colleague @bernd_heinen in his white paper linked here:

https://www.jmp.com/en_us/whitepapers/jmp/pharmaceutical-quality-by-design-methods.html

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us