- JMP will suspend normal business operations for our Winter Holiday beginning on Wednesday, Dec. 24, 2025, at 5:00 p.m. ET (2:00 p.m. ET for JMP Accounts Receivable).

Regular business hours will resume at 9:00 a.m. EST on Friday, Jan. 2, 2026. - We’re retiring the File Exchange at the end of this year. The JMP Marketplace is now your destination for add-ins and extensions.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: How do I model defect rates from a doe

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

How do I model defect rates from a doe

Hi, I have results from a DOE that was run to see the effect of some factor on a defect rates. Samples were analysed (500 parts) and different defects were counted. So for example defect #1 = 40/500=0.08

I would like to model the data but from the research I did I think rates (between 0 and 1 ) should be modelled using a logistic regression. I cannot seem to do that in JMP16 as if just give me options to run logistic for ordinal or nominal. So what is the best way to fit a model to predict rate data?

Thank you

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How do I model defect rates from a doe

Assuming that you have a response for each observation (e.g., defect, no defect), then I recommend using this data column with the nominal modeling type. I would start by analyzing each type of defect separately. This will cause JMP to use the appropriate logistic regression method.

- Open data table

- Be sure that response data column has the nominal modeling type set

- Select Analyze > Fit Model

- Select the binomial data column (response) and click Y

- Select the factor data columns and click Add (you can also use higher order terms for interaction and non-linear effects if necessary).

- Click Run

You can save the selected model as a new data column with a formula. You can then select Graph > Profiler and use all the saved prediction formulas simultaneously in your exploration and optimization.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: How do I model defect rates from a doe

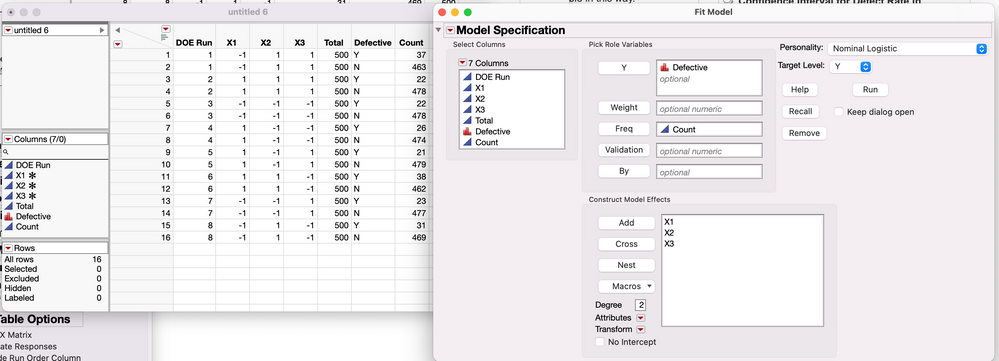

Mark's suggestion is good, but make sure that you set up the data table properly so that you can do that analysis. I am going to assume that for each DOE run you have the total number of parts and the number of defects. You then need to calculate the number "not defective", and arrange the data table with two rows for each DOE run, and the response (Defective) equal to "Y" in one row and "N" in the second row, along with a Count variable to record the number of defective or not defective. See the screen shot and attached example table. When you specify the mode., you need to also choose the "Target Level", in this case the indicator for defective, and use the Count variable in the frequency (Freq) role.

Recommended Articles

- © 2025 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us