- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: Finding the allowable limits for a factor to ensure low defect rates

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Finding the allowable limits for a factor to ensure low defect rates

Hi,

Anyone has any idea how do we find the allowable limits that a few factors can operate in order to maintain a certain defect rates. This video from robert actually shows how to find the best settings in order to achieve lowest defect rate with the assumption of normal distribution in these factors. What I am looking for is how do i determine what is the maximum variation allowable in order to achieve this defect rate.

Using historical production data to identify manufacturing process improvements:

Rgrds

Irfan

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Finding the allowable limits for a factor to ensure low defect rates

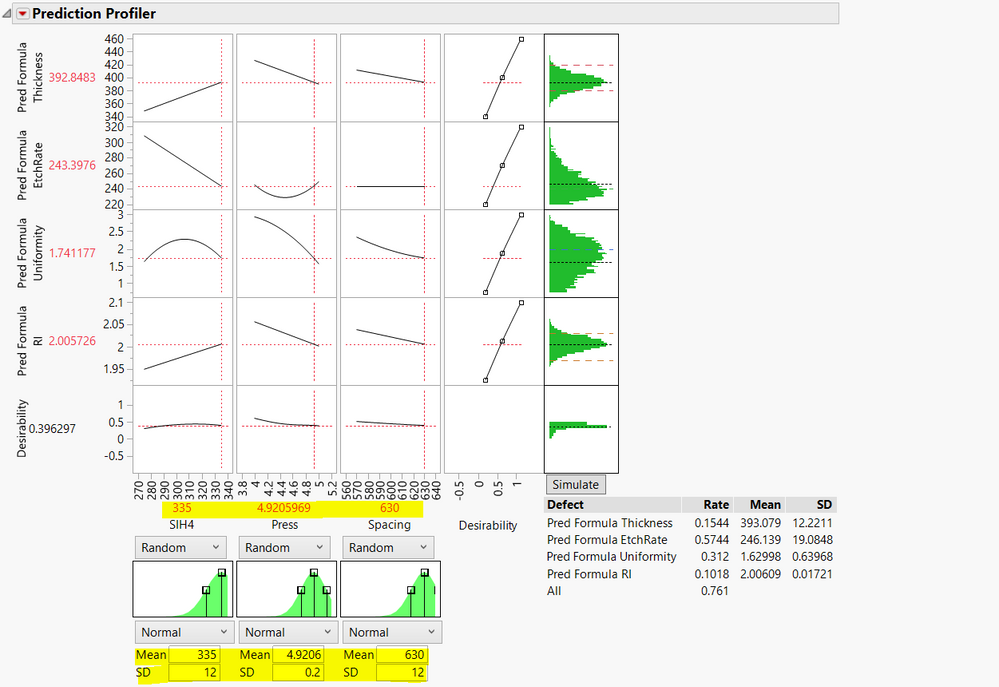

The video shows how to use the Prediction Profiler to obtain factor settings that maximize the desirability that you defined for each response. This tool has a built-in Monte Carlo simulator that addresses your current question. You can define factors to be fixed (always achieve desired set point) or variable. You can define the variation with a distribution model (e.g., normal distribution) or a custom expression using the JMP scripting language. Some of the variation is inherent in the response and not due to variation in factor levels. This variation is added separately.

See Help > Books > Profilers > Prediction Profiler for more details and examples.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Finding the allowable limits for a factor to ensure low defect rates

Actually if i want to determine what is the limit of my factors to be in order to ensure that all my response are within the spec limits, is there a way to find this? From the simulator we actually specify the type of variations of the factors be it a normal, binomial or any other distribution

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Finding the allowable limits for a factor to ensure low defect rates

The variability is defined by the control you think you have. The capability analysis after the simulation will determine if this control is sufficient. If the capability is too low, then you can return to the simulator and try imposing more control (less variation) on one or more factors before running the simulation again. You might have to iterate a few times before coming to factor ranges that work.

Did you read the chapter in the Help I suggested?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Finding the allowable limits for a factor to ensure low defect rates

I was going through the book manual on the profilers and came across this, what I am looking for is that with the current response specification limits what are the factors limit which I should use whereby it will not be to tight and too loose causing to many failures

Rgrds

Irfan

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Finding the allowable limits for a factor to ensure low defect rates

We are 'going around in circles.' You keep telling me that you want to determine the factor ranges that will maintain process capability. I already explained how to perform this analysis. I directed you to chapter 8 in the Profilers guide, which thoroughly explains and demonstrates the Defect Profiler in The Simulator. What is not clear? What do you not understand? What is the specific problem that you are having?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Finding the allowable limits for a factor to ensure low defect rates

Hi Mark,

This is the experiment that I am currently conducting, the method that normally we use is that we use the defect log rate to find the best settings for the factors, but what I am looking for what is the best SD for each factors (eg in this example my normal SIH4 SD = 12, Press SD = 0.2, Space SD = 12. And we know that the defect rate can even be reduce more when we tighthen the SD for our factors. So what I am looking for is what is the SD that I have to run for all these 3 factors in order to meet the specification limit for all my 4 response (Thickness, Etchrate, Uniformity, RI)

I know that we can 'manually' adjust the SD 1 by 1 to see what is the SD to achieve a 0% defect rate, but is there an automated way to do this

Hope this explains my question/problem

Rgrds

Irfan

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Finding the allowable limits for a factor to ensure low defect rates

There is no automated procedure. The idea is that the engineer / scientist uses this tool to set up different scenarios and evaluate capability / defects. JMP cannot know how easy or hard, cheap or expensive it is to control the factor levels.

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us