- JMP will suspend normal business operations for our Winter Holiday beginning on Wednesday, Dec. 24, 2025, at 5:00 p.m. ET (2:00 p.m. ET for JMP Accounts Receivable).

Regular business hours will resume at 9:00 a.m. EST on Friday, Jan. 2, 2026. - We’re retiring the File Exchange at the end of this year. The JMP Marketplace is now your destination for add-ins and extensions.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Easy: Determine Main Effects

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Easy: Determine Main Effects

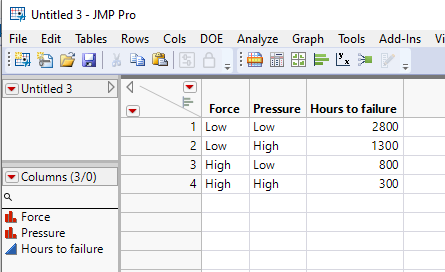

After a full factorial design was executed I have the following tabulated results:

Force | Pressure | Hours to failure |

15 N (Low) | 10 Pa (Low) | 2800 hours |

15 N (Low) | 150 Pa (High) | 1300 hours |

100 N (High) | 10 Pa (Low) | 800 hours |

100 N (High) | 150 Pa (High) | 300 hours |

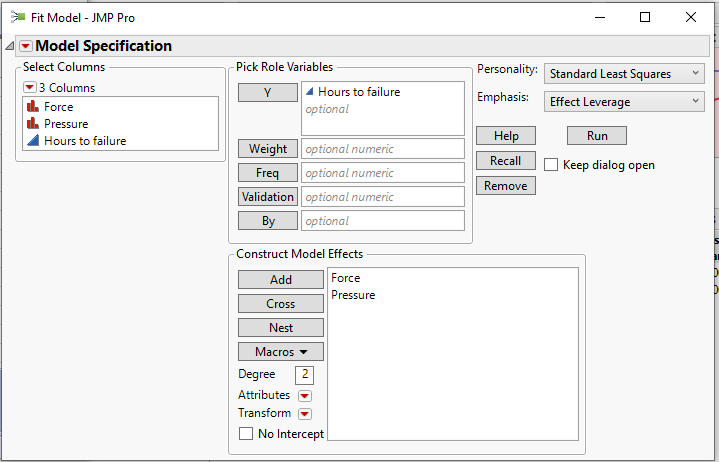

How would I determine the main effects of Force and Pressure? I've added this data to a table, my next move would be to Analyze > Fit Model and figure out to make a Least Squares Mean Plot. Having a hard time setting that up in the Fit Model.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Easy: Determine Main Effects

Enter your data into a data table

Go to

Analyze=>Fit Model

enter in the model you want to analyze

And click OK

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Easy: Determine Main Effects

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Easy: Determine Main Effects

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Easy: Determine Main Effects

Enter your data into a data table

Go to

Analyze=>Fit Model

enter in the model you want to analyze

And click OK

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Easy: Determine Main Effects

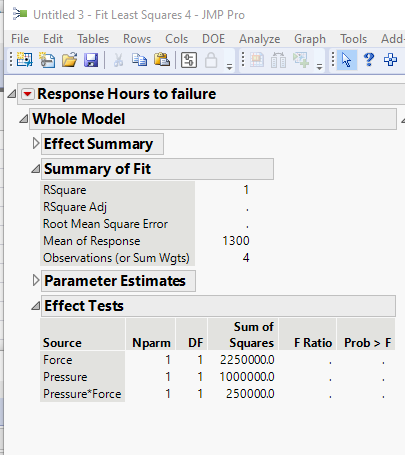

Eric, welcome to the community. Jim provided the steps to do exactly what you want. I would simply add...why not also get the interaction effect while you're at it. 3 total DF's P+F+PF

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Easy: Determine Main Effects

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Easy: Determine Main Effects

Ummm, yes there are. I always start with a saturated model, use Normal, Bayes and Pareto plots as well as look at parameter effects and SS. Use engineering knowledge and predictions about potential effects to then reduce the model. I really don't place much weight on p-values as YOU control these via how you collect your data. So, for example, if you leave the interaction out of the model, guess what...the interaction is the estimate of mean square error and is therefore the basis of the statistical test (F-test). For unreplcated designs, I much prefer the unbiased Daniels plots, but that's just me.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Easy: Determine Main Effects

I stand corrected.....

Recommended Articles

- © 2025 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us