- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: Defining Factor Constraints in Custom Design DOE

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Defining Factor Constraints in Custom Design DOE

Hi community,

JMP novice here, apologies if I'm missing something very obvious.

I'm trying to set up a DOE for a chemical reaction that has 5 components, just call them A, B, C, D, and E. For their quantity, I am expressing each one as a fraction of the whole, or the percent of the total volume that the component takes up. So I would like to include a Linear Constraint so their sum does not exceed 100%, I am using:

1A + 1B + 1C + 1D + 1E <= 100

Then the second thing I'd like to do is to make some of these mutually exclusive. For example I only want A OR B, and C OR D, I never want them both present at the same time. So I am trying to add a Disallowed Combination Filter to achieve this. I just add A and B and move the slider so that it is not allowed for A and B to both have non-zero values. Then do the same for C and D.

I feel like I am able to set up each one individually but the program only pays attention to the one that has the radio button highlighted...is it not allowed to have both types of constraints? Or is there a better way to do this? Thanks in advance for any help. Any guidance in the GUI or scripting example would be great.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Defining Factor Constraints in Custom Design DOE

Hi,

Thank you for this great question! It is possible to define factors in custom design as "mixture" components. JMP sees the mixture components and allows them to vary within the low and high levels, but ensure the total always sums to 1 (you can change this value if you like, but the default is 1).

However, you're question is a bit more complicated as, if I've understood correctly, A and B cannot both be in the mixture at the same time (e.g. if A >0 than B=0), and also at least one must be in the mixture (e.g. if A=0 than B!=0). The same is true for C and D.

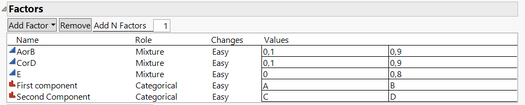

Take a look at how I've defined the factors below and see if it meets your criteria. I've used 3 mixture components (AorB, CorD, E) and two categorical factors ("First Component" and "Second Component"). The lower levels of AorB/CorD ensure that the mixture comprises at least 10% A or B, and 10% C or D. The categoricals define whether A or B / C or D are used. Does this work?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Defining Factor Constraints in Custom Design DOE

Hi,

Thank you for this great question! It is possible to define factors in custom design as "mixture" components. JMP sees the mixture components and allows them to vary within the low and high levels, but ensure the total always sums to 1 (you can change this value if you like, but the default is 1).

However, you're question is a bit more complicated as, if I've understood correctly, A and B cannot both be in the mixture at the same time (e.g. if A >0 than B=0), and also at least one must be in the mixture (e.g. if A=0 than B!=0). The same is true for C and D.

Take a look at how I've defined the factors below and see if it meets your criteria. I've used 3 mixture components (AorB, CorD, E) and two categorical factors ("First Component" and "Second Component"). The lower levels of AorB/CorD ensure that the mixture comprises at least 10% A or B, and 10% C or D. The categoricals define whether A or B / C or D are used. Does this work?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Defining Factor Constraints in Custom Design DOE

Hi Hadley,

Thanks for your response! This approach makes sense but I have a couple followup questions. I had considered using a mixture but my understanding is that when factors are defined as a mixture they must add up to 1 by default, or any user-defined constant. In my scenario, using your value limits as an example, it's possible that I would want to test AorB = 0.1, CorD=0.1, E = 0.1. The remainder of the mixture would be water. If I used the Linear Constraint, I can force the three concentrations to be ≤ 1 without forcing it to be = 1. If I use these factors as mixtures, I would have to add another factor F to represent water, just to get it to add up to 1, but I don't want the model to think that this is a critical factor, I just want it to be a filler. Would it make sense to add this factor F, or would it be better to use your method of using the categoricals but still use a Linear Constraint to limit the sum of AorB, CorD, and E? Or is there a way to add factor F but force its concentration to be 1 - (AorB + CorD + E)?

Second question, I think the way you defined the factors will work and the design it generates will make sense, and we can execute that. When we input the data, will the model understand (or does it need to understand) that the concentration value of factor AorB is actually associated with categorical First component value "A" or "B"? Does it need to make that connection? I might be creating a problem here that doesn't exist.

Thank you for your help!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Defining Factor Constraints in Custom Design DOE

Hi,

You can simply set the sum to be less than 1, and then water would make up the difference. In that case, A+B+C+D+E would be constant. If the concentration of water varies from run to run, meaning that the ratio of chemicals/water is something you want to include as a factor, then adding "F" (water) as a mixture factor would mean A+B+C+D+E+F=1. In that case, you wouldn't need a linear constraint. Does this make sense?

Regarding your question: "will the model understand (or does it need to understand) that the concentration value of factor AorB is actually associated with categorical First component value "A" or "B"?," it will depend on whether the effect of concentration changes depending on whether you are using A or B. The way to check that is to include an interaction component in the model ("AorB" x "First component"). If this interaction term comes out as significant, it would mean that the effect of the concentration of A or B does indeed depend on which chemical you are using; for example, higher concentrations are more optimal when using "A" but lower concentrations are better when using "B."

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Defining Factor Constraints in Custom Design DOE

In addition to @HadleyMyers' advice, you are taking what is known as the 'inert ingredient' approach. Water is the inert ingredient that will make up the remainder of the mixture. So do NOT use mixture factors. You can independently change the level of the components in this case.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Defining Factor Constraints in Custom Design DOE

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Defining Factor Constraints in Custom Design DOE

Hadley, Mark, Phil, thank you for all your input. Looking at the interaction between the concentration factor and the categorical factor makes sense. I will give this a try using the Linear Constraint rather than mixture factors, and use the categoricals as Hadley suggested.

Thank you all for your time, this is much appreciated!

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us