- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: Control charts issue

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Control charts issue

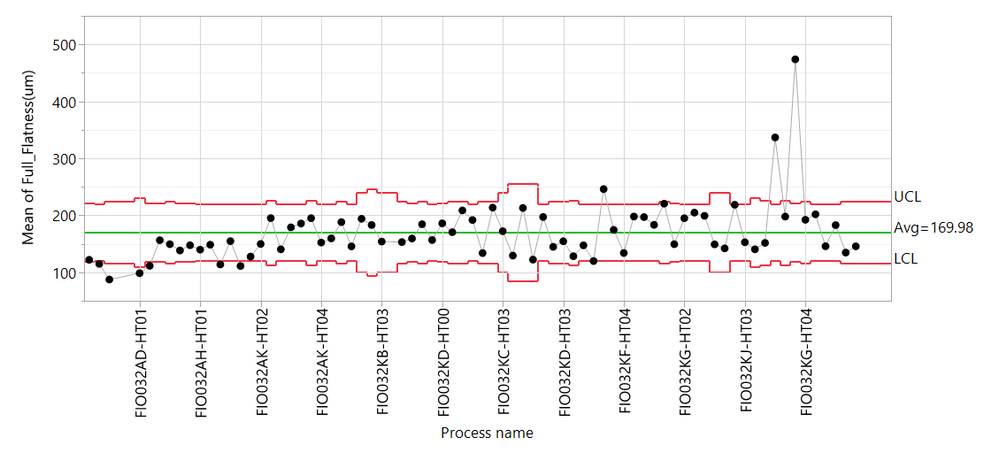

I have an issue plotting control charts. The controls limits are not constant but varies from point to point. See below. Can anyone help me troubleshoot?

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Control charts issue

You have a different number of observations for each mean point that is plotted. Thus, varying control limits. Think of it this way, there is more certainty if your mean is made up of 10 observations compared to a mean made up of 3 observations. So the control limits should be different.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Control charts issue

You have a different number of observations for each mean point that is plotted. Thus, varying control limits. Think of it this way, there is more certainty if your mean is made up of 10 observations compared to a mean made up of 3 observations. So the control limits should be different.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Control charts issue

Thanks Dan - your explanation makes sense. I didnt realize the calculation was for each mean point but obvious now that you pointed it out.

I do have a follow-up question. I am thinking that it would be worthwhile to have a single control line that I could use detect drifts in process and out-of control point. Is this worth in your opinion? If so, how would I go about doing so?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Control charts issue

You can set the Control Limits Column Property for your measurement column. The Control Chart will then display that line, and use it for any tests that you apply to the chart.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Control charts issue

Regarding your followup question, technically speaking you can place the control limits (as @txnelson notes) anyplace you desire. So now the questions becomes which value and on what basis did you determine those limits? One of Dr. Deming's famous rhetorical questions he always encouraged those of us in quality to ask is "By what method?" And he was serious. JMP uses the tried and true methods originally developed by Walter Shewhart (for the xbar/R charts and others) so you would have a defensible answer to that question. Otherwise, you are picking some other method. Now the question becomes, "On what basis is your method desirable over other methods?" Shewhart's methods were built on the concept of seeking to find an economic balance of making Type I and Type II errors in a system. If you can substantiate that YOUR limits find that economic balance then go for it. If not...I don't see a rational reason to use limits other than those found in JMP using a typical Phase I control chart study.

Others may feel differently...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Control charts issue

For me, this is an incredibly powerful tool - for years in the 90s I needed something like this, ended up buying an awful one-off piece of software and then ditching that and hand-coding it for an instrument output application. Ugh - now we have a similar use and have access to this chart. Takes just one time explaining to people, and they can appreciate what is happening. (#thanksJMP!)

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us