The strength of the JMP Pro Functional Data Explorer platform (FDE) is identifying and extracting key features of functional processes for use in further modeling.This is done by fitting a functional model to the data using a B-spline, P-spline, or Fourier basis model; performing a functional principal components analysis on the functional model; saving the PCA results; and using the results for feature extraction and analysis in another modeling platform.

Hadley Myers @HadleyMyers and Don McCormack @DonMcCormack, two JMP Systems Engineers, recently contributed to a paper in IEEE describing how they used JMP Pro to better understand how photovoltaic (PV) devices are affected by changes in deposition conditions and the influence this has on device quality. What are photovoltaic devices? They are systems that convert sunlight directly to electricity using photovoltaic cells made of semiconductor materials.

Hadley and Don leveraged the use of Functional Data Explorer (FDE) because of its usefulness for analyzing curves that vary across a continuum, such as those recorded during current voltage (JV) and External Quantum Efficiency (EQE) measurements. NOTE: EQE curves show the ratio of the number of charge carriers collected by the solar cell to the number of photons of a given wavelength.

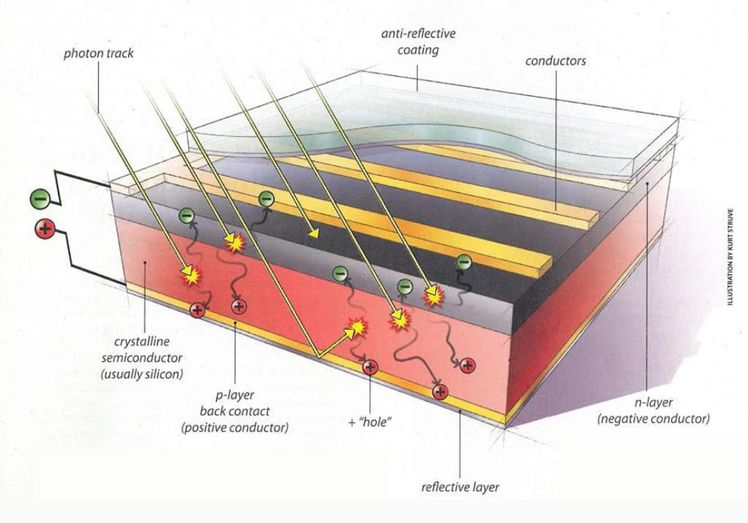

Diagram of a typical crystalline silicon (c-Si) cell. (Courtesy of Solar Energy Industries Association)

Diagram of a typical crystalline silicon (c-Si) cell. (Courtesy of Solar Energy Industries Association)

One of their goals was to apply functional data analysis, and specifically to test JMP Pro FDE as a new tool to gain insight into the complex interplay of the various factors.

They followed this sequence:

- Characterize the photovoltaic cells by measuring current-density–voltage (JV) characteristics under AM1.5 illumination for the different back contact sets at the various maximum growth temperatures during deposition.

- Remove device outliers.

- Model performance for remaining devices, enforcing statistical heredity to limit the total number of models.

- Perform functional data analysis on the entire JV and EQE curves using the FDE platform in JMP Pro.

- Fit models to output of FDE to identify key factors contributing to the functional responses that had been missed in Step 3.

What they found:

- FDA helped isolate and quantify the effect of deposition temperature on the EQE of the devices. Specifically, temperature was seen to be the only factor that significantly influenced variation. The curve shapes showed that higher temperatures appeared in general to result in increased bandgaps of the absorber and decreased collection in the entirety of the absorber layer.

- Higher growth temperature seems to improve the final diode, but might adversely affect semiconductor material quality.

- Effect of back-contact deposition conditions (%O2 in sputtering chamber and film thickness) on the JV-response that had been missed when only considering the usual device parameters.

The study increased the understanding of photovoltaic devices, uncovered new and previously undetected effects, and is just one example of how to use JMP Pro FDE in the pursuit of better (and hopefully environmentally sound) devices and systems.

The techniques used in this study of Copper Indium Gallium Selenide (CIGS) photovoltaic devices can be applied to the analysis of other types of PV structures, including those constructed using Crystalline Silicon (c-Si).

Get the full details on the study and its results in "Functional Data Analysis of Electrical Measurements on Thin-Film Photovoltaic Devices" by Hadley Franklin Myer, Don McCormack, Muhammad Saifullah, Tobias Bertram, Rutger Schlatmann and Christian A. Kaufmann.

By the way, photovoltaic solar arrays at SAS world headquarters in Cary, NC, generate 3.8 million kilowatt-hours of clean, renewable energy annually.

By the way, photovoltaic solar arrays at SAS world headquarters in Cary, NC, generate 3.8 million kilowatt-hours of clean, renewable energy annually.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.