Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Options

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

JMP Scripters Club Discussions

- JMP User Community

- :

- JMP Users Groups

- :

- JMP Users Groups by Capability

- :

- JMP Scripters Club

- :

- Discussions

- :

- Re: SPC scripting - Why writing information back into a database is important

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

SPC scripting - Why writing information back into a database is important

Created:

Dec 9, 2022 09:42 AM

| Last Modified: Dec 9, 2022 6:59 AM

(2071 views)

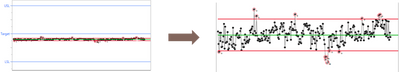

Problem description - Process is unstable:

- Influence of time or unknown variable

- Process moves slowly towards out of spec

- An incident shift the process

Overview SPC:

- SPC is like telling a dog to “stay”. Wherever the process is, it should remain in that place.

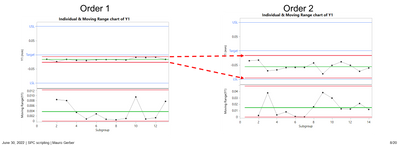

- A stable phase should be defined and notify the operator when the process is out of control limits before it’s out of spec.

Problems with SPC:

- Process screening platform gives a lot of false positives and is therefore not always useable for prioritizing improvements

- Default SPC control limits on our data are often too strict:

- When new data are analyzed, the control limits shifts automatically.

- A change in the process can be overlooked.

The solution should:

- Generate, store and update individual control limits.

- Help in setting limits for multiple variables.

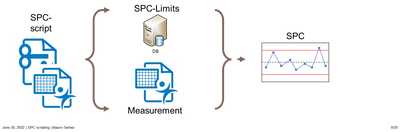

SPC scripts

- The Script generates a table with each variable that contains spec limits.

- It tries to load existing control limits into the table from the DB

- It adds scripts to store and set the limits.

Slides and Demo are available on the attachment.

"I thought about our dilemma, and I came up with a solution that I honestly think works out best for one of both of us"

- GLaDOS

- GLaDOS

1 REPLY 1

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: SPC scripting - Why writing information back into a database is important

Great demo Mauro, thanks for sharing the script !

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us