Wouldn’t it be wonderful to be able to determine capability and stability on thousands of processes in a single graph? How much time could you save? JMP 13 provides the new Process Screening platform that does just this. You can use this platform to quickly determine your overall process health. This will allow you to focus more time on problem solving rather than viewing process output to determine where the fires are.

My blog post "Generating control limits using Control Chart Builder" details how to determine process stability. My blog post "Creating a capability analysis in JMP using your specification limits" details how to determine process capability. If you have hundreds or thousands of processes that you would like to look at for both capability and stability, this process can be quite tedious. This blog post describes how to use the Process Screening platform to determine stability and capability for many processes at the same time.

Example

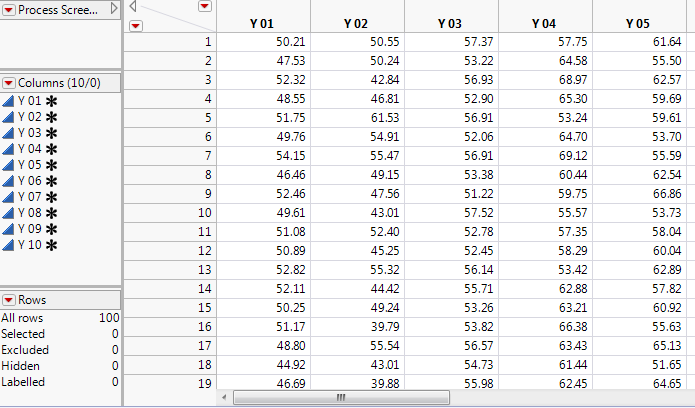

In the previous two blog posts, "Generating control limits using Control Chart Builder" and "Creating a capability analysis in JMP using your specification limits", I described an example from a printing process. The example specifically focused on line lengths. This blog post uses data that contains information about 10 characteristics of the typesetting process (including line lengths, widths, measures of skew and color). Each of these ten measurements are taken on a test page. The past 100 runs of the test page are contained in the data table. Specification limits have already been added as column properties in the process columns.

Typesetting data

Typesetting data

Generate a Process Screening report

Go to Analyze->Screening->Process Screening. Select all columns (Y 01 through Y 10) and click Process Variables. Click OK. You are presented with a single report window that contains a vast amount of information in a compact format.

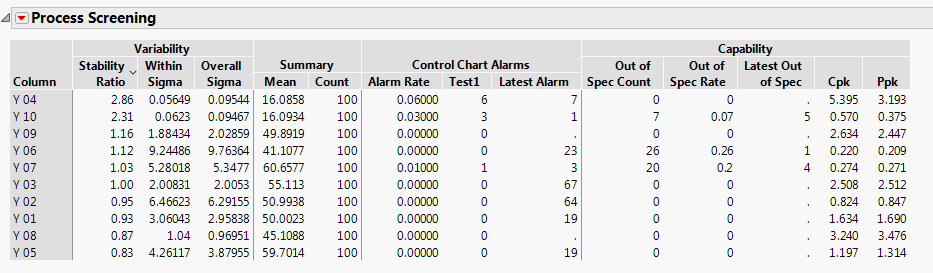

Process Screening Report

Process Screening Report

The report is initially sorted by the Stability Ratio. You can alter this by clicking on any of the headers in this report. This report is divided into four different sections. The sections are Variability, Summary, Control Chart Alarms, followed by Capability.

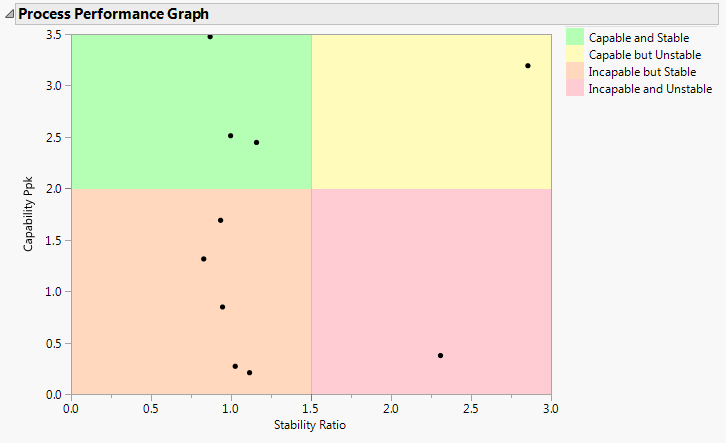

Process Performance Graph

Click on the red triangle next to Process Screening, and choose Process Performance Graph.

Process Performance Graph

Process Performance Graph

Initially, the graph boundaries are set at a Stability Ratio of 1.5 and a Capability Ppk of 2. You can alter each of these values by choosing Performance Graph Boundaries from the red triangle next to Process Screening. Three of the processes are both capable and stable (points that fall in the green quadrant). Five of our processes are incapable but stable (points that fall in the orange quadrant). One process is capable but unstable (point falls in the yellow quadrant). One process falls into the worst category, which is both incapable and unstable (point falls in the red quadrant).

Quick Graphs

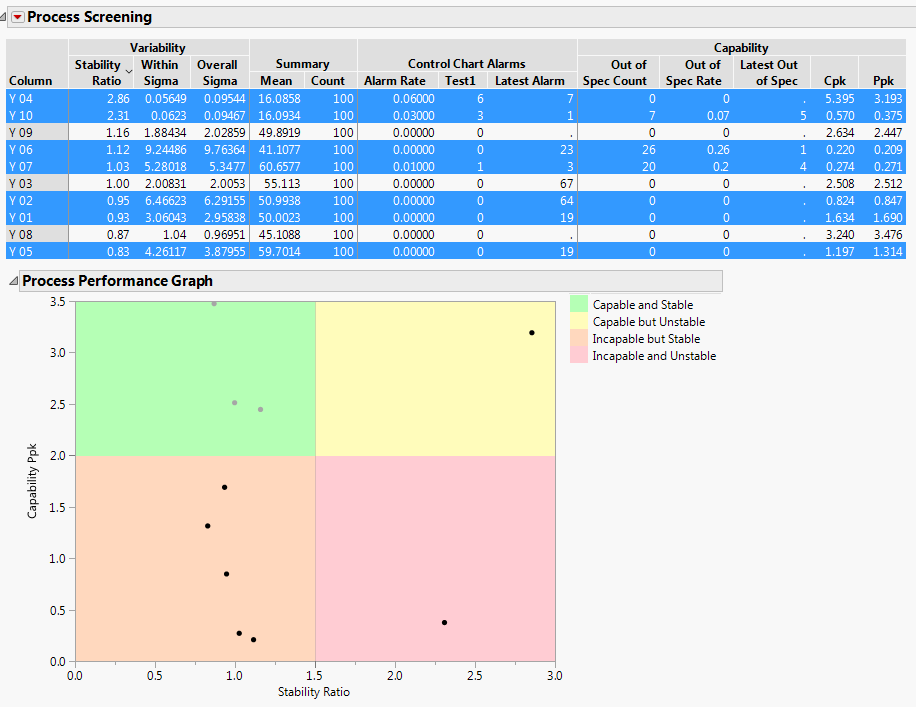

Select all of the points that fall in the yellow, orange and red categories using the lasso tool. This also highlights the processes in the report above the graph.

Highlighted processes in the Process Screening Report

Highlighted processes in the Process Screening Report

Click on the red triangle next to Process Screening, and choose Quick Graph for Selected Items.

Quick Graphs for Selected Items

Quick Graphs for Selected Items

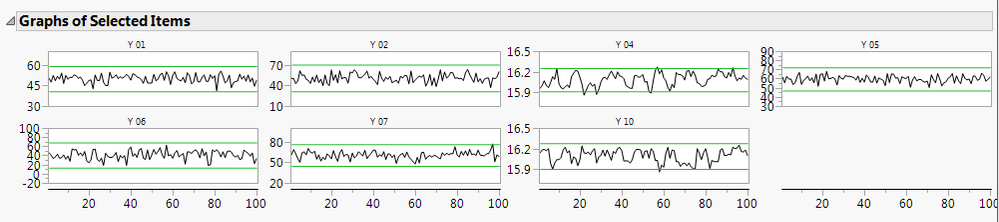

The graphs are small (sparkline) control charts that allow you to view the graphs of many processes at once. The green horizontal lines represent the control limits. Only two of the graphs show out of control points. Y 04 (the point that appears in the yellow quadrant) and Y 10 (the point that appears in the red quadrant) show the out of control points. Not coincidentally, these are the two processes that the graph showed were unstable.

Control Charts

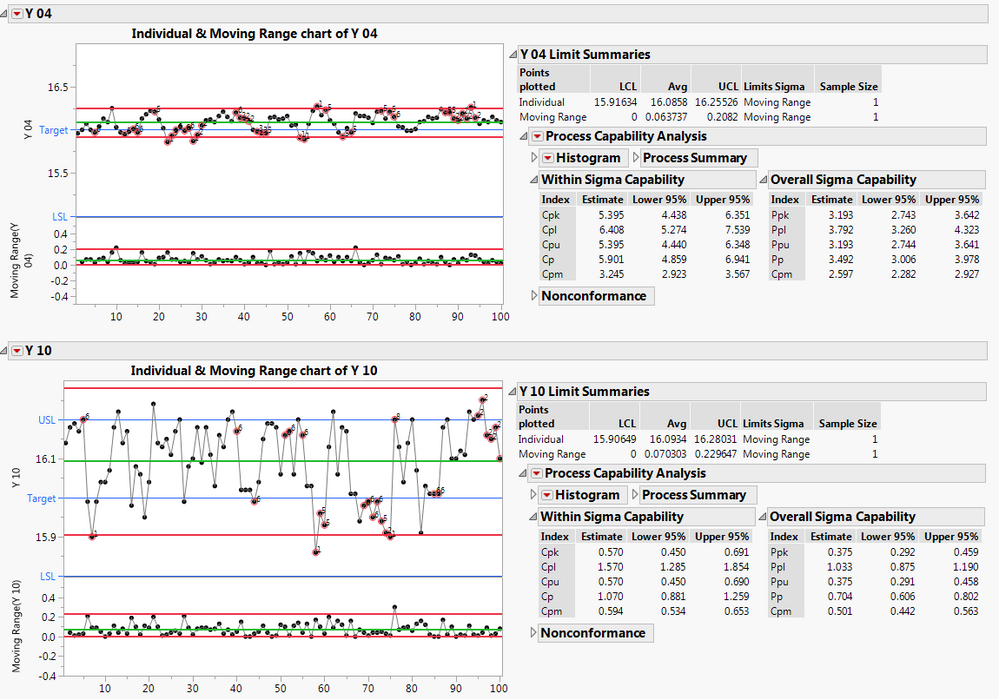

We learned in the blog "Generating control limits using Control Chart Builder" that we should look at stability before capability. If your process is not stable, then your capability results may not be accurate. To do this, select Y 04 and Y 10 in the report, click on the red triangle next to Process Screening and choose Control Charts for Selected Items. This launches Control Chart Builder.

Control Charts for selected items

Control Charts for selected items

We see that not only are there test 1 violations as shown in the Process Screening platform, there are also test 2, 3, 5, 6, 8, and range limit violations. Clearly, these two processes are not stable. The capability results can’t be taken as true until the process is stable.

Investigation of the stable, but incapable processes

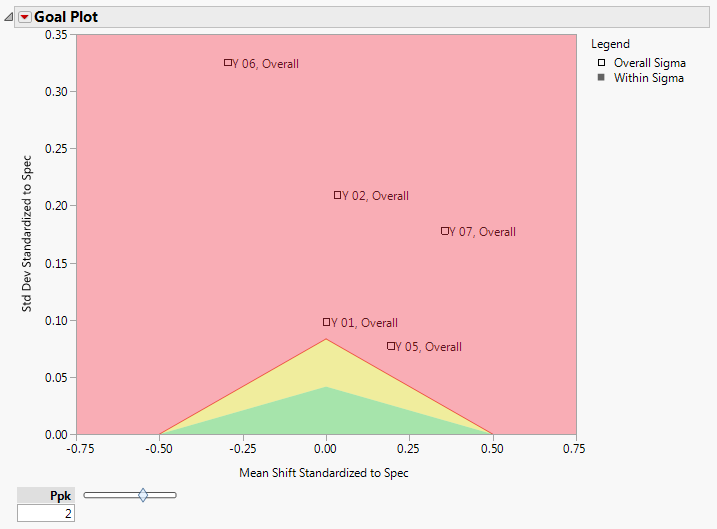

Next let’s investigate the processes that fall into the orange quadrant. These processes are stable, but not capable. Select these five processes using the lasso tool, and choose Process Capability for Selected Items from the red triangle next to Process Screening. In the new window that is opened, scroll down to the Goal Plot. Notice that the Ppk slider is initially set to 1. Alter this value to 2 so that it matches the boundary for the Process Performance Graph given in the Process Screening platform. Click on the red triangle next to Goal Plot, and select Label Overall Sigma Points. Click again on the red triangle next to Goal Plot, and select Shade Levels. (Alternatively, you can hold down the Alt key while clicking on the red triangle next to Goal Plot and pick both of these options at once).

Process Capability for selected items

Process Capability for selected items

Notice that Y 01 and Y 02 appear close to target (near 0 on the x axis), but have high variability (fall above the apex of the triangle). Y 05 is off target, but the variability is acceptable. Y 07 and Y 06 are both off target and have high variability. For each of these processes, investigation should be done to either bring the process on target and/ reduce the variability in the process.

Conclusion

The Process Screening platform allows you to assess the capability and stability of thousands of processes at once. The Process Performance Graph gives a succinct picture of the overall performance of each of the processes. You can perform further investigations of stability or capability by launching Process Capability or Control Chart Builder directly from Process Screening. Process Screening will allow you to get all of the process information you need from one location in order to save you time and money.

References

JMP Software: Statistical Process Control Course Notes

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.