- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: Why the in-process output considered as potential cause?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Why the in-process output considered as potential cause?

Hello,

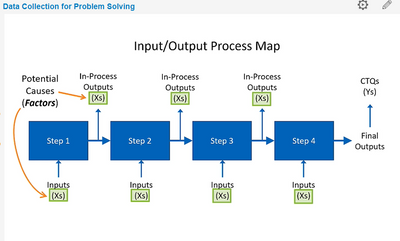

Please see below image.

1.Can someone help me to understand why In-process outputs are considered as potential Causes (X's).

2. In the below case how can we find that there is a problem with machine or parameters of the machine?

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Why the in-process output considered as potential cause?

Hi @dheerules,

1. Looking at the process diagram, it seems that steps are dependant from each other, meaning the inputs for step 2 are independant inputs and outputs from step 1. Because of this "cascading" process, you have in-process outputs that are considered as potential causes.

2. It might be difficult to answer to this question without more information from the process (is it a process from a single machine that do an operation in several steps ?). But if you have your Y's that are off-target, you might need to investigate why they are off-target and what might be the root cause. For this, having a process map/diagram might help to investigate the several steps of the process, by running analysis of historical results and planning experiments (through DoE) to establish causal relationships between X's and Y's and build a model of the process.

Hope this quick answer will help you,

"It is not unusual for a well-designed experiment to analyze itself" (Box, Hunter and Hunter)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Why the in-process output considered as potential cause?

This looks like it's straight out of some kind of Six Sigma course. Let me try and give an example for answers to both questions...

For question 1: Step one is a milling operation where some material is ground to some aim size, the size of the material as it exits the milling operation in the 'in process x' from step 1. The material from step one, passes to step two where it's melted into a liquid form. The 'in process x' from step two is now the viscosity of the melted material. And on and on.

For question 2. One method that could be employed is establishing some sort of process monitoring along the flow. So measuring either process conditions along the path or any of the outputs. Control charts could play a big role here.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Why the in-process output considered as potential cause?

Hi @dheerules,

1. Looking at the process diagram, it seems that steps are dependant from each other, meaning the inputs for step 2 are independant inputs and outputs from step 1. Because of this "cascading" process, you have in-process outputs that are considered as potential causes.

2. It might be difficult to answer to this question without more information from the process (is it a process from a single machine that do an operation in several steps ?). But if you have your Y's that are off-target, you might need to investigate why they are off-target and what might be the root cause. For this, having a process map/diagram might help to investigate the several steps of the process, by running analysis of historical results and planning experiments (through DoE) to establish causal relationships between X's and Y's and build a model of the process.

Hope this quick answer will help you,

"It is not unusual for a well-designed experiment to analyze itself" (Box, Hunter and Hunter)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Why the in-process output considered as potential cause?

Thanks Victor

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Why the in-process output considered as potential cause?

This looks like it's straight out of some kind of Six Sigma course. Let me try and give an example for answers to both questions...

For question 1: Step one is a milling operation where some material is ground to some aim size, the size of the material as it exits the milling operation in the 'in process x' from step 1. The material from step one, passes to step two where it's melted into a liquid form. The 'in process x' from step two is now the viscosity of the melted material. And on and on.

For question 2. One method that could be employed is establishing some sort of process monitoring along the flow. So measuring either process conditions along the path or any of the outputs. Control charts could play a big role here.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Why the in-process output considered as potential cause?

Thanks Bartell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Why the in-process output considered as potential cause?

The nomenclature is, unfortunately not universal. I would describe in-process outputs as little y's, the output of the culmination of steps as the Big Y's and the input variables as x's. You can have the following equations:

Y=f(y)=g(x)

There is likely a hierarchy of causal structure.

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us