- Due to inclement weather, JMP support response times may be slower than usual during the week of January 26.

To submit a request for support, please send email to support@jmp.com.

We appreciate your patience at this time. - Register to see how to import and prepare Excel data on Jan. 30 from 2 to 3 p.m. ET.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: Functional Data Explorer: applicable to study impact of a non-constant varia...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Functional Data Explorer: applicable to study impact of a non-constant variable on a function?

Hello,

We would like to understand what may have caused a change in aspect of an online process data curve over several runs.

The variable that we have identified as having changed over the past runs was the stirring speed. This variable however is not constant over time, but is varying over time. It is part of a regulation cascade to maintain another variable constant (the dissolved oxygen). This means it is not controlled over time but dependent on how much oxygen is needed. All controlled parameters seemed to be the same in all runs.

Would we be able to use Functional Data Explorer or another tool in JMP to investigate on the changes we've been seeing?

Many thanks in advance for your support!

Best regards,

Claire Baril

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Functional Data Explorer: applicable to study impact of a non-constant variable on a function?

Hi Claire,

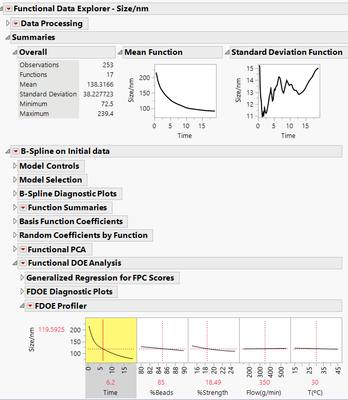

Yes, the Functional Data Explorer should be able to do this, assuming you have a record of the uncontrolled stirring speed. The attached file has a sample script attached that shows an example of using parameters to model the curve (yellow in screenshot below)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Functional Data Explorer: applicable to study impact of a non-constant variable on a function?

Hi Claire,

Yes, the Functional Data Explorer should be able to do this, assuming you have a record of the uncontrolled stirring speed. The attached file has a sample script attached that shows an example of using parameters to model the curve (yellow in screenshot below)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Functional Data Explorer: applicable to study impact of a non-constant variable on a function?

I will expand the suggestion by @Jed_Campbell. You have a set of output functions for the process runs and the corresponding stirring speed function for each run. You make a set of functional principal components (fPC) for the online process data curves, save them, and use them as your response in the Y role. You also make a set of functional principal components for the stirring speed functions, save them, and use them as your predictor in the X role. You need to be able to match each Y fPC with its corresponding X fPC for each process run. This arrangement is a matter of using commands in the Table menu. You can use most of the fitting platforms to propose and test models of a relationship between the stirring speed and the process curves.

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us