- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- DOE custom design with covariates

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

DOE custom design with covariates

Hi community,

I'm seeking to gain knowledge on what factors influence the force required to push on an inhalator mouthpiece to an inhalator.

I have 8 boxes (A through H), each containing 1 inhalator and 12 mouth pieces (A1 to A12, B1 to B12, and so on). There are 3 types of inhalators across these 8 boxes (3 brown + 3 green + 2 red), but all the 96 mouthpieces are supposed to be identical.

It is unknown if we can expect variation in push-on force from "inhalator type", "inhalator box" or even "mouthpiece box" or a combination of these.

Moreover, the mouthpiece can be put on at various angles and the requirement for the test sequence is to try out 8 different angles.

My question is how best to set up a Custom Design in JMP to test the possible influence of these factors. We are commissioned to do 96 runs, which is a lot, but can be executed in a day. I think the original idea was to test inhalator A with all its mouthpieces (A1 to A12), B with all its mouthpieces, etc., which would amount to 96 runs, but I believe we can do better with DOE.

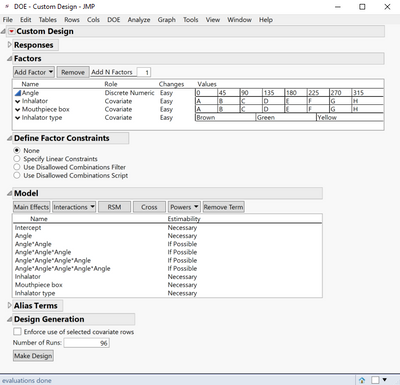

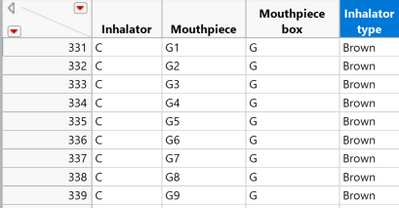

What I've done so far is to create a data table of all possible combinations of inhalator and mouthpiece, 768 in total (example of a row: inhalator from box C, which is a brown type, with mouthpiece G5, see screenshot). From this table I've tried to create a custom design with Inhalator (A, B, ..., H), Mouthpiece Box (A, B, ..., H), and Inhalator Type (Brown, Green, Yellow) as Covariate factors and Angle as a Discrete Numeric factor with 8 levels (0, 45, 90, ..., 315).

When trying to make the above design with 96 runs, JMP thinks for a little and then states that "The selected terms in the Model outline are linearly dependent on the previous terms. Please press the Remove Term button and try again."

It helps if I remove Inhalator as a factor, and I suspect this is were I'm going wrong? Can't I have a design that models both box-to-box variation and type-to-type variation for inhalators? Am I down the wrong path and have to rethink the DOE setup altogether?

All help is appreciated, thanks in advance!

I'm running JMP 14.2.

/Morten

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE custom design with covariates

I think the problem here is -- as you have worked out -- that there is a dependency between Inhalator box and Inhalator type. The model with both Inhalator box (8 levels) and Inhalator type (3 levels) is not estimable. My understanding is that you are interested in the variance in push force between boxes rather than knowing the effect of box choice on push force. In which case, you would ultimately model Inhalator box as a random effect. Similarly I expect that you would model Mouthpiece box as a random effect. In order to design the experiment I think you can take out either Inhalator type or Inhalator box from the model. If you want to get a good balance across Inhalator type, you should remove Inhalator box.

I hope that helps,

Phil

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE custom design with covariates

I think the problem here is -- as you have worked out -- that there is a dependency between Inhalator box and Inhalator type. The model with both Inhalator box (8 levels) and Inhalator type (3 levels) is not estimable. My understanding is that you are interested in the variance in push force between boxes rather than knowing the effect of box choice on push force. In which case, you would ultimately model Inhalator box as a random effect. Similarly I expect that you would model Mouthpiece box as a random effect. In order to design the experiment I think you can take out either Inhalator type or Inhalator box from the model. If you want to get a good balance across Inhalator type, you should remove Inhalator box.

I hope that helps,

Phil

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE custom design with covariates

Thanks a lot for your reply, @Phil_Kay

I understand what you're saying and this confirms my suspicion. I'll remove one of the Inhalator factors from the design.

Just to be sure: When you state that I could/should model Mouthpiece box as a random effect, you mean when I create a model on the response values, right? Not when I create the DOE design?

Thanks again,

Morten

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE custom design with covariates

Correct - I am suggesting that you model Mouthpiece box as a random effect when you have collected the response data.

You can't really specify random effects in the model in Custom Design.

You could try specifying Inhalator box and Mouthpiece box as blocking factors, which is essentially the same as declaring them as random effect factors. But it might get complicated. I have not tried designing an experiment with more than 1 blocking factor. It appears to be possible but I can't tell you more than that - sorry!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE custom design with covariates

I'm a little rusty on blocking factors. Could you elaborate a little on the benefits of specifying the two factors as blocking factors rather than covariate factors (supposing that JMP can do this)? I would only have randomized runs "inside" each block right?

/Morten

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE custom design with covariates

@mbnielsen , first welcome to the community. Phil has already provided some ideas for you. I have the following thoughts (keep in mind I do NOT know the specific situation you are dealing with, so some of my comments might be irrelevant):

1. I assume you are measuring force...do you know the variability, discrimination or consistency of this measurement system? Is there a minimum (so it doesn't fall off) and a maximum (so it doesn't distort the components of create a defect) requirement for the force? Are there other response variables of interest (e.g., Do you care about the flow of air (or gas)?

2. As I understand it you are investigating to discover what factors affect the force required to push a mouthpiece on to an inhalator. Understanding causal structure is very different than "pick the winner". In understanding causality, you do not likely need every combination to draw inferences from the study. And likely the investigation will be iterative. Is it simply a dimensional or geometrical interference issue? Do you understand the stack up of interfaces?

3. Do you hypotheses associated with the variables in the study? Why would there be a box-to-box variation? What is actually changing box to box? It sounds like the inhalator is changing box-to-box...what specifically might be changing inhalator-to-inhalator? There are also sets of mouthpieces changing box-to-box, why might they be different? I understand they are all intended to be identical, but this of course is impossible? How are the mouthpieces made? Are the injection molded, or vacuum molded, or what? Are they all coming from the same tool? Does the tool have multiple cavities? Is there variation in the polymer (or whatever the material might be) the mouthpieces are made of (e.g., lot-to-lot)? There seem to be 3 different types of inhalators. What makes them different? Can the differences be quantified? You then introduce angles and have 8 of them...Why 8? How representative are these 8 of reality? Could you just use the extremes of angles in an initial study to get an estimate of the size of the effect and then if it is significant do further testing to identify the best conditions? Of is the angle noise (uncontrollable)? Many of these questions should be considered before deciding the appropriate data collection strategy. In your situation, I believe sampling might be a more appropriate strategy.

4. If you are convinced you want to experiment, what do you need to create a design space that is reasonable, representative and efficient!

Could you get away with 2 angles set at bold levels, 2 inhalators (the extremes of the 3) or you could do all 3? You could confound the box with blocks (though you don't need 8 of them IMHO) and treat the mouthpieces as repeats. Start with estimating linear effects and then build on the model through iteration.

5. Covariates are measured on a continuous scale and typically these are variables are considered noise in an experiment situation. By including the covariate in our models for analysis, we can account for the covariate variability thereby increasing the precision of detecting the factor effects.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: DOE custom design with covariates

Thanks, @statman, and thank you very much for the detailed reply!

- There is only a maximum limit for the force (cannot disclose the exact value), and we will not be measuring any other responses.

- I agree that we wouldn't need all combinations, but since we have 96 runs to work with (this is already decided by higher-ups) I think we can "afford" to do it all in once, rather than iteratively.

- This is a good point, we really do not know of or expect systematic variation between inhalators of the same type or between mouthpieces. But we might see variation, though, since boxes might come from different lots and/or tools; unfortunately we do not have any manufacturing information on the components. This is why I want to model these factors: I don't know that they should contribute to variation, but I'm not sure they don't, either.

Regarding the angles, the choice of 8 comes from there being certain geometric features in the mechanical interface between inhalator and mouthpiece. We could do with less, but again, since there are 96 runs I believe we can afford the completeness. - What would be the benefit of blocking in this experiment? Wouldn't we just lose some randomization? Regarding the inhalator types, we don't know which of the 3 types are extremes, so we want to test all 3 types.

- Sounds right to me, however my covariates are categorical (JMP seems to cope)?

Thanks again!

Morten

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us