- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Interpration of DoE results

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Interpration of DoE results

Martin Here:

I have to brother JMP staff with my recent DOE project once more.

I am developing a cementitious adhesives, I used JMP custom design; I picked three factors:

Blue circle (white cement): 0.6898~0.7431 (proportion)

Ternal white (HAC cement): 0.2564~0.3009 (proportion)

sodium citrate (retarder): 0.0023~0.0093 ( proportion)

these three factors are entred in custom design as Mixture, added up proportionally to 1.

The responses are three adhesions.

adhesion after immersion (>=1MPa)

adhesion after 6hrs (>=0.5 MPa)

adhesion after 30 mins open time (>=0.5MPa).

The design and response results are listed in below table:

| Factors | Response | ||||

| Blue circle | Ternal white | Sodium citrate | Adhesion after imm (Mpa) | 6 hrs adhesion (Mpa) | 30 mins open time (Mpa) |

| 0.7389 | 0.2546 | 0.0065 | 1.02 | 0.68 | 1.136 |

| 0.7192 | 0.2785 | 0.0023 | 0.85 | 0.692 | 0.121 |

| 0.6940 | 0.3009 | 0.0051 | 0.843 | 0.432 | 0.664 |

| 0.7431 | 0.2546 | 0.0023 | 0.922 | 0.572 | 0.092 |

| 0.6968 | 0.3009 | 0.0023 | 0.89 | 0.716 | 0.201 |

| 0.7165 | 0.2778 | 0.0058 | 0.917 | 0.574 | 0.923 |

| 0.7431 | 0.2546 | 0.0023 | 0.909 | 0.678 | 0.096 |

| 0.7165 | 0.2778 | 0.0058 | 0.88 | 0.548 | 0.804 |

| 0.6898 | 0.3009 | 0.0093 | 0.88 | 0.224 | 1.079 |

| 0.7138 | 0.2769 | 0.0093 | 0.911 | 0.278 | 0.839 |

| 0.7361 | 0.2546 | 0.0093 | 0.941 | 0.428 | 0.953 |

| 0.6898 | 0.3009 | 0.0093 | 0.859 | 0.21 | 1.264 |

The first formulation gives best results, adhesion after immersion=1.02 MPa, adhesion after 6 hrs =0.68 MPa, and adhesion after 30 mins open time 1.13 MPa.

The rest all failed adhesion after water immersion.

Could any of JMP staff briefly run this design? I have trouble to interperate the JMP regression results, since there are no significant factors or interactions in JMP output.

Big thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Interpration of DoE results

Hi Martin,

No the script looks complex because it has been recorded after I have manipulated the model through my mouse clicking activities. So although it appears more complex I did not script anything but rather saved the script to the data table after I had closed down some windows and opened some others and obtained the output that was the most meaningful to assess your experiment.

Lou

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Interpration of DoE results

Hi Lou:

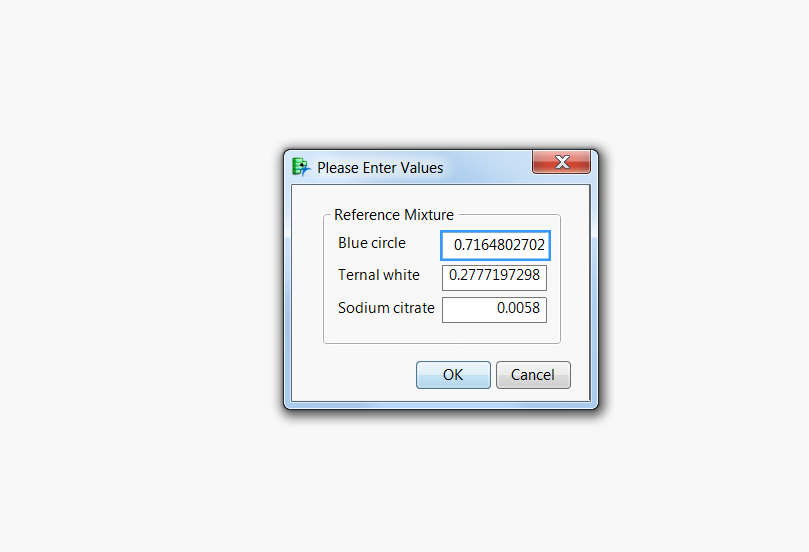

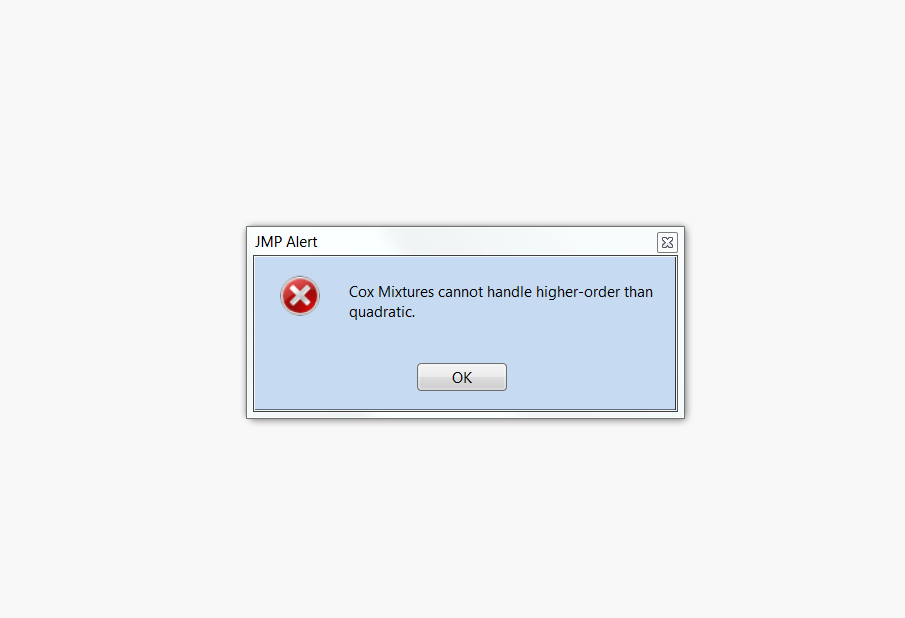

I always get wrong message at Cox mixture interface. after the wrong message, Cox mixture button turn grey.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Interpration of DoE results

If you remove the three-way interaction term in the model the Cox Mixture Model will not give this error message.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Interpration of DoE results

Dear Stephen:

Thanks for taking time reviewing my question.

You are right that my ranges of three factors are very narrow. The reason for it is it is very difficult to pass adhesion after 6hrs ( >=0.5MPa) and adhesion after immersion (>=1MPa)

simultaneouely. In an industrial environment, it is imperative to get workable formulation that passes all the requirement listed in the standard, in this case, I get a workable formulation ,but because of its narrow range, I have great difficulty of interpreting the mechanism behind it.

Do I need to make runs that I know before hand it will fail certain requirements? I am a little bit too target driven in this project, may be, hehe.

The tests procedures are well established, I am in the process of validating the workable formulation, but even it works, I am also interested why it works. that is why I want to

salvage something from this DOE, and plan a future one which will shed light on the mechanism of interaction between three factors.

Thanks

Martin

- « Previous

-

- 1

- 2

- Next »

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us