Level: Advanced

Job Function: Analyst / Scientist / Engineer

Beatrice Blum

blum_b_1

, Senior Statistician, Procter & Gamble

Henning Vohwinkel

vohwinkel0

, Senior Product Developer, Procter & Gamble

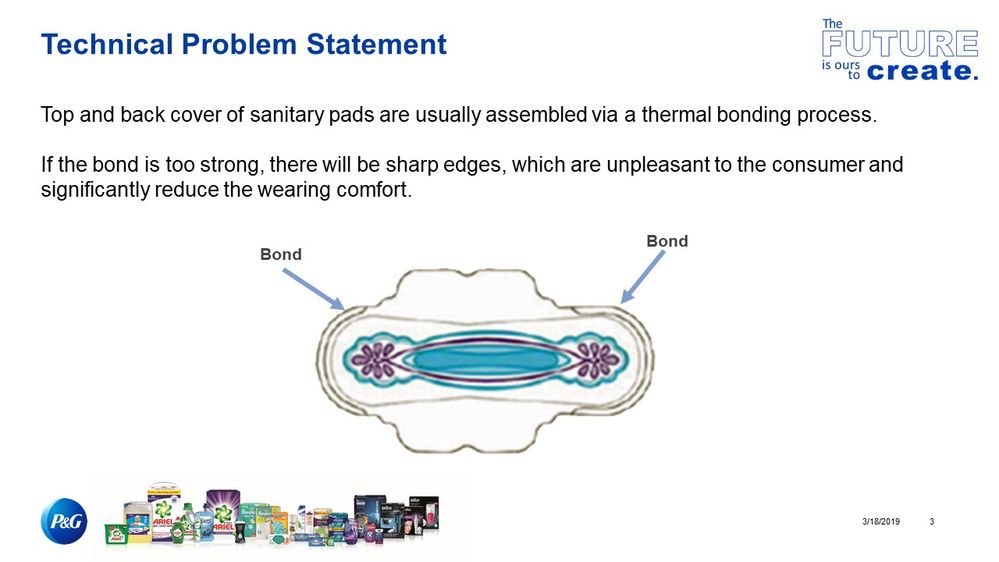

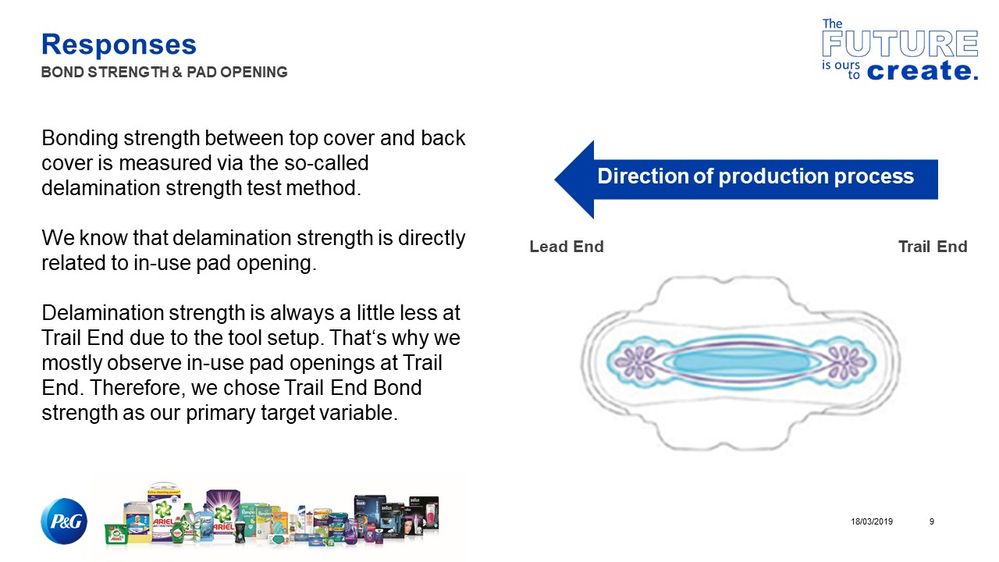

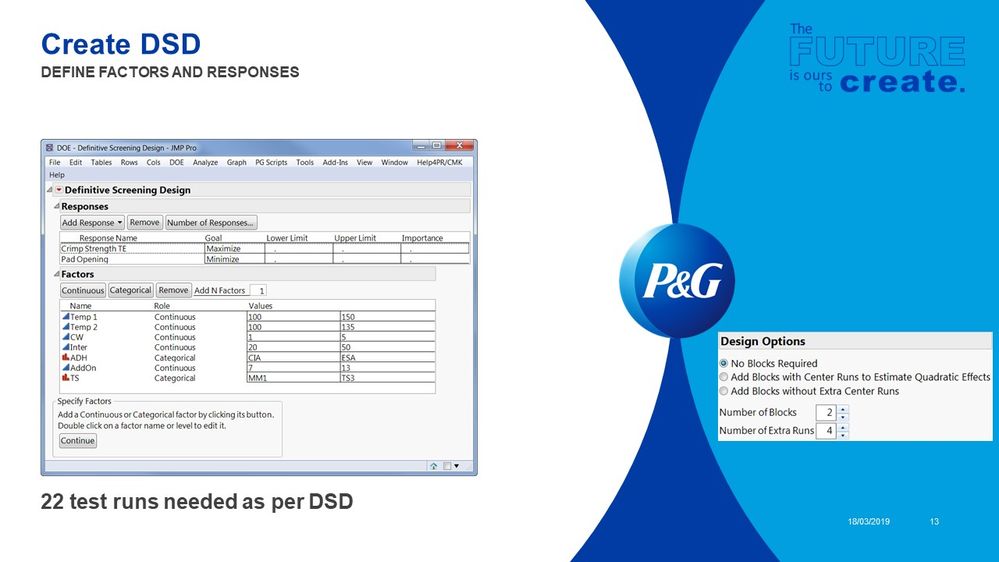

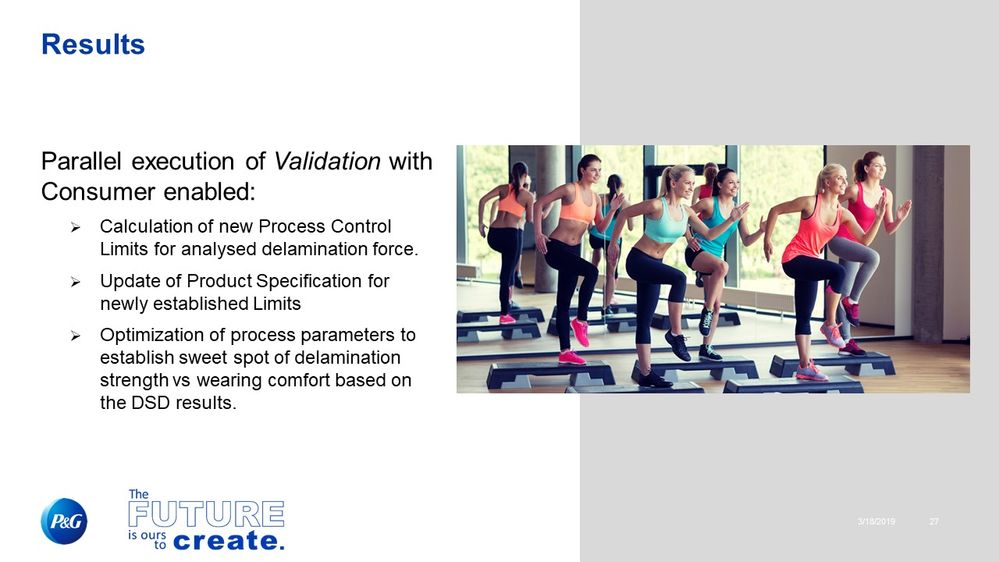

Sanitary pads consist of different layers of raw material which are joined in a continuous production process. Various technologies are available to bond the top layer with the bottom layer. The requirement for the bonding is to keep the pad intact throughout the entire wearing time, even in extreme conditions at gym workout. Additionaly, the pad's flexibility and softness should be retained.

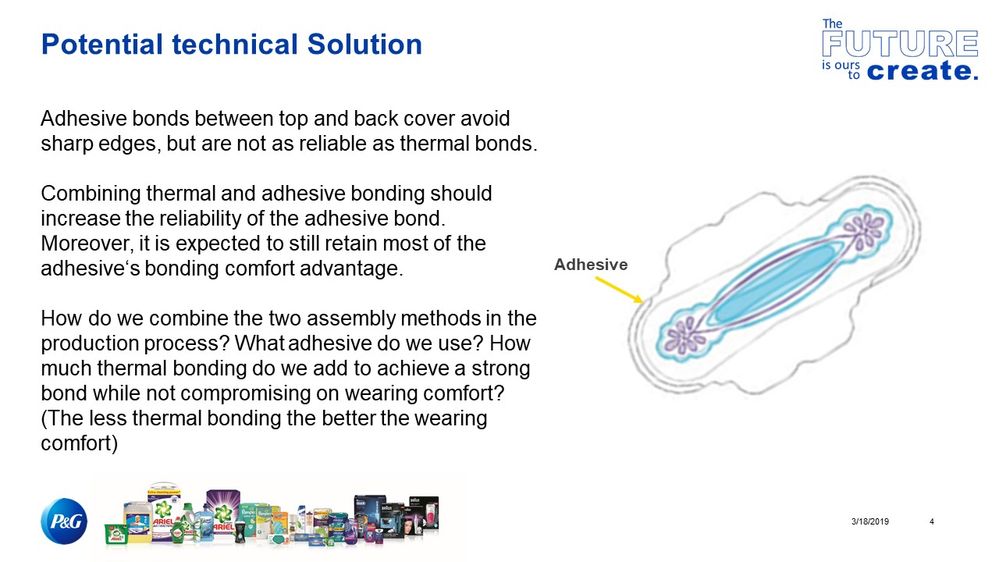

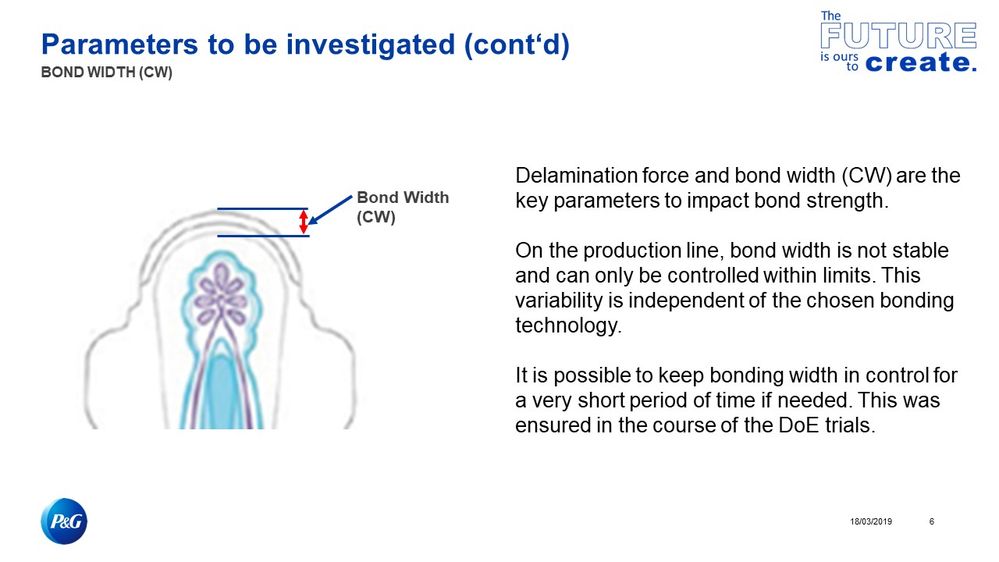

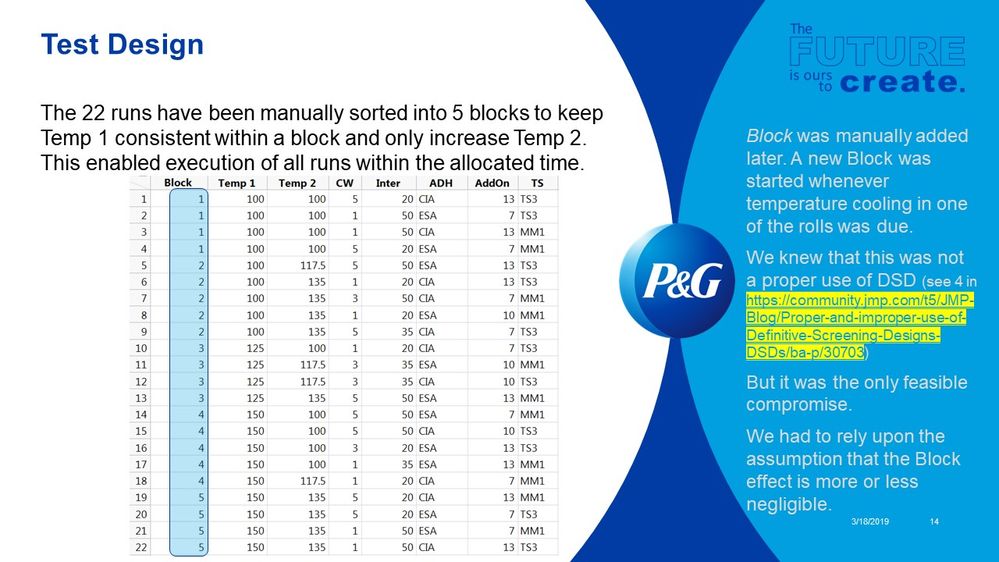

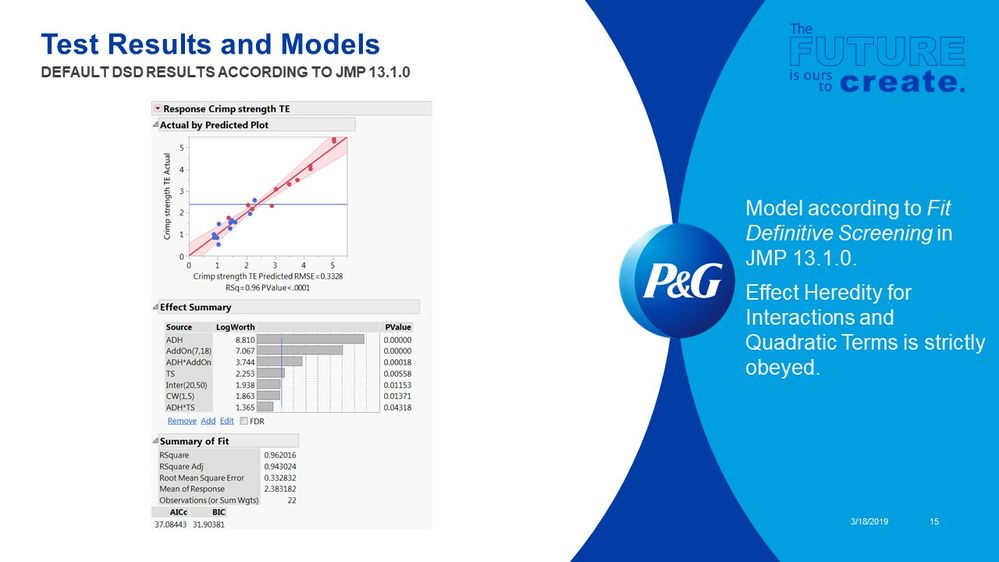

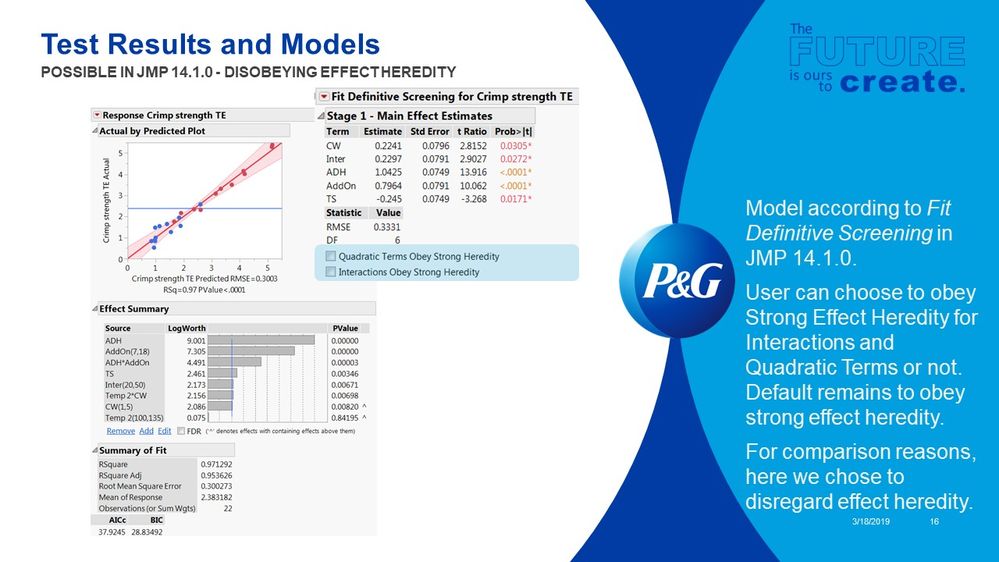

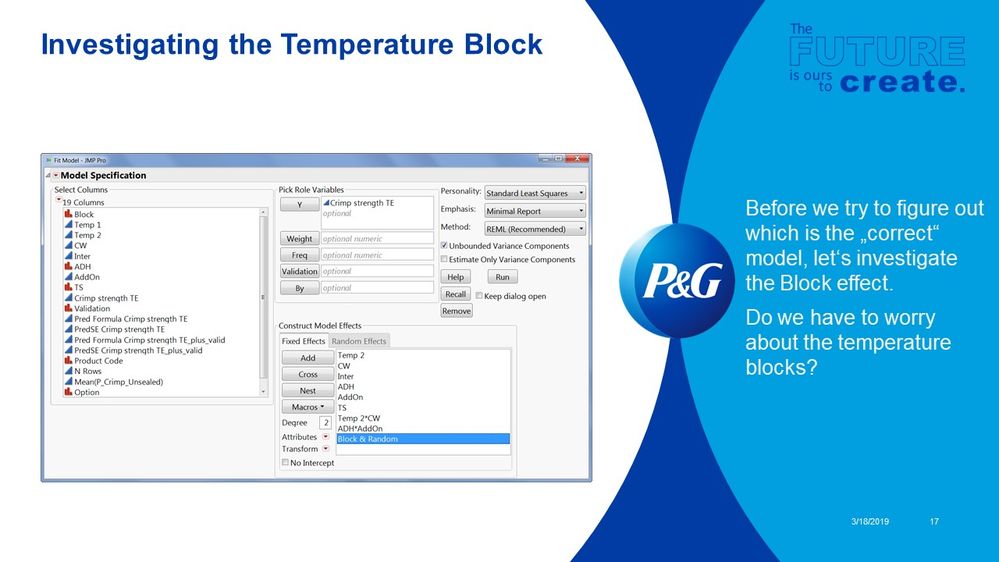

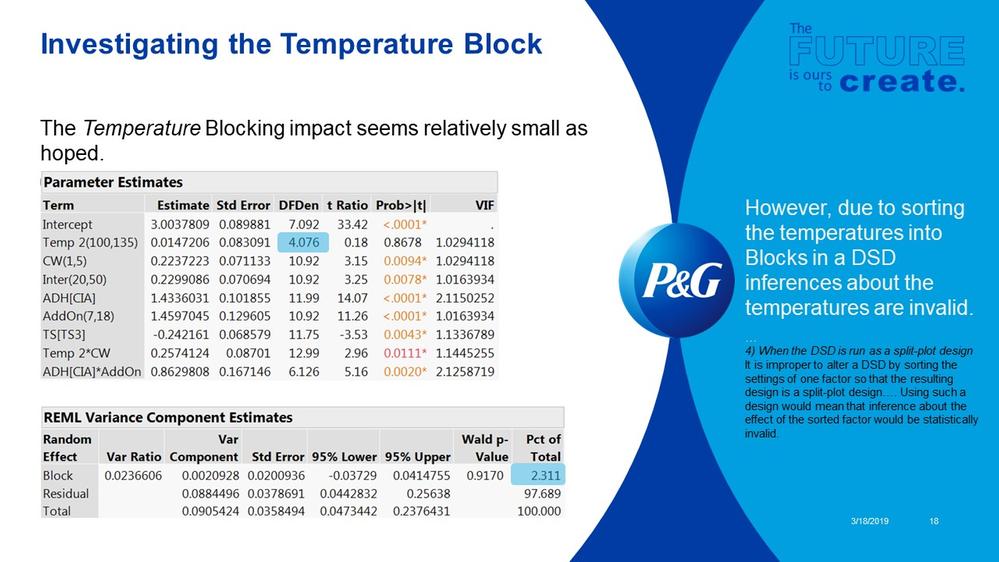

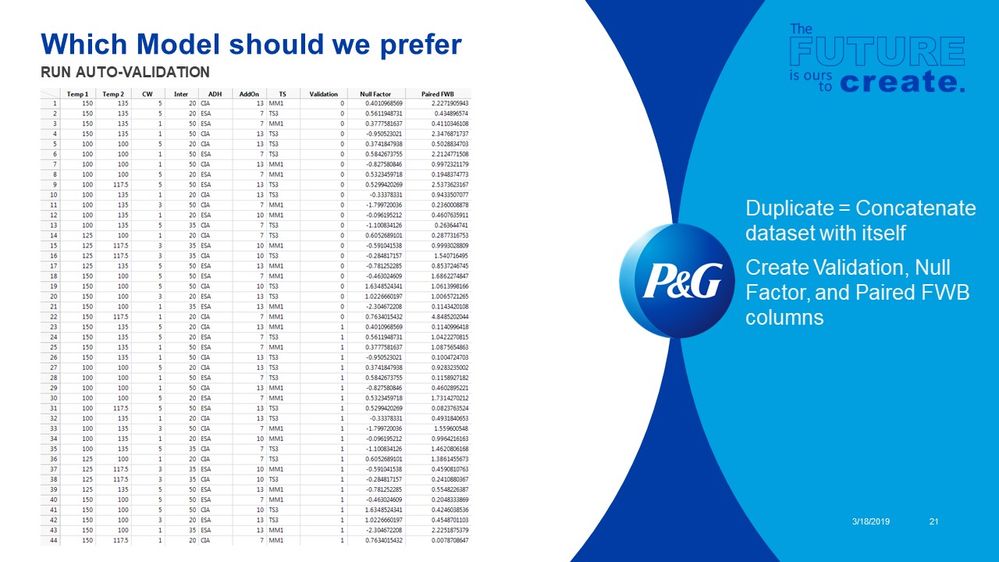

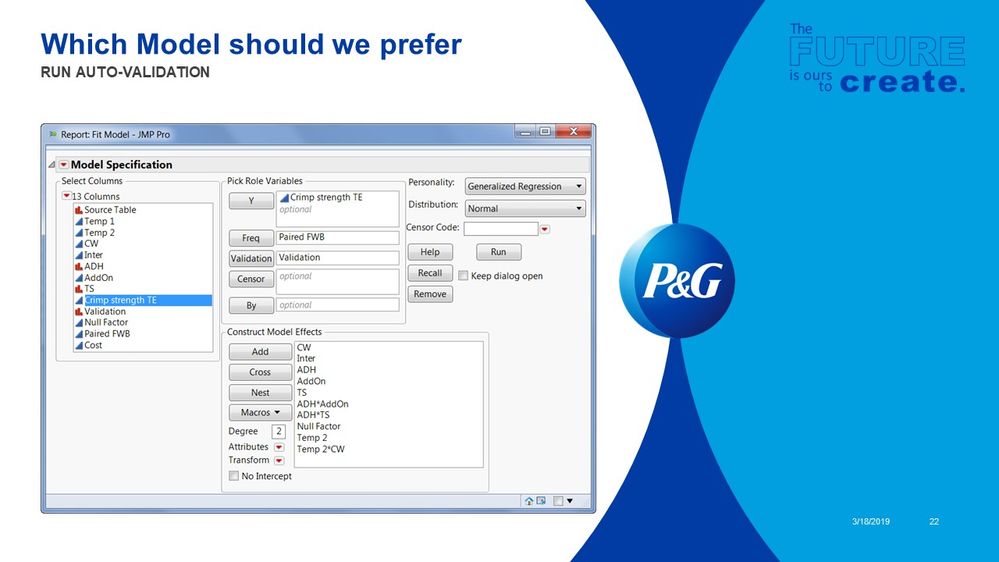

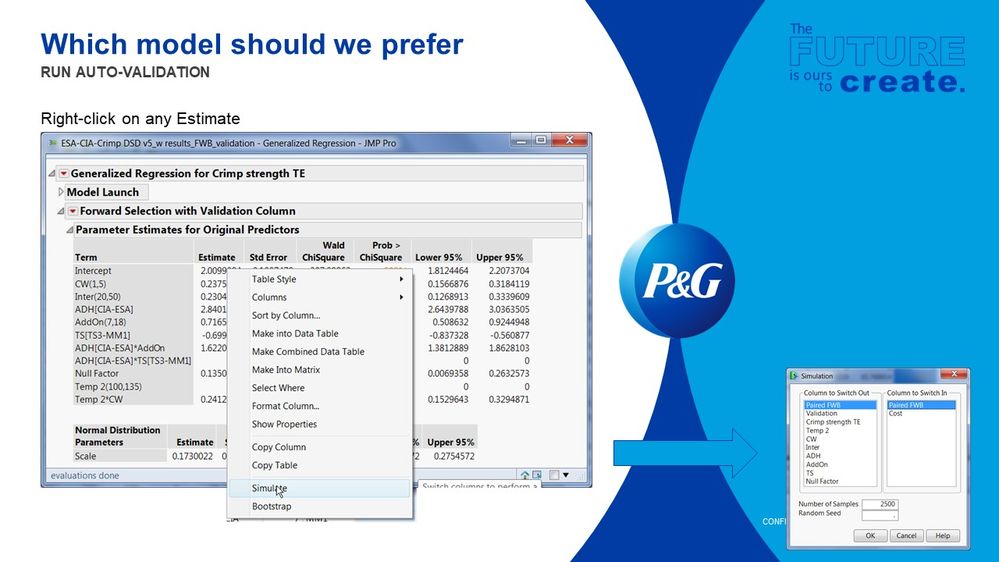

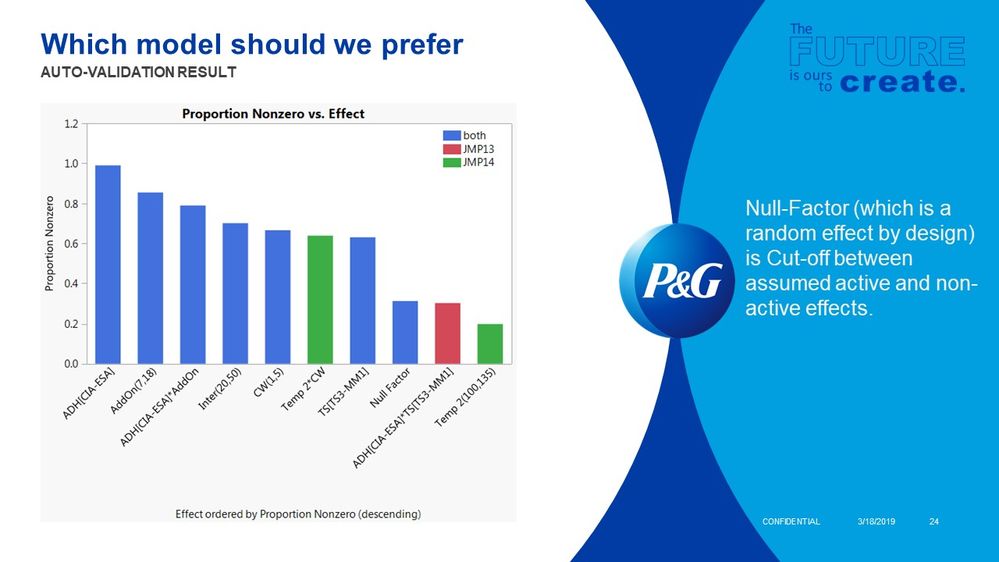

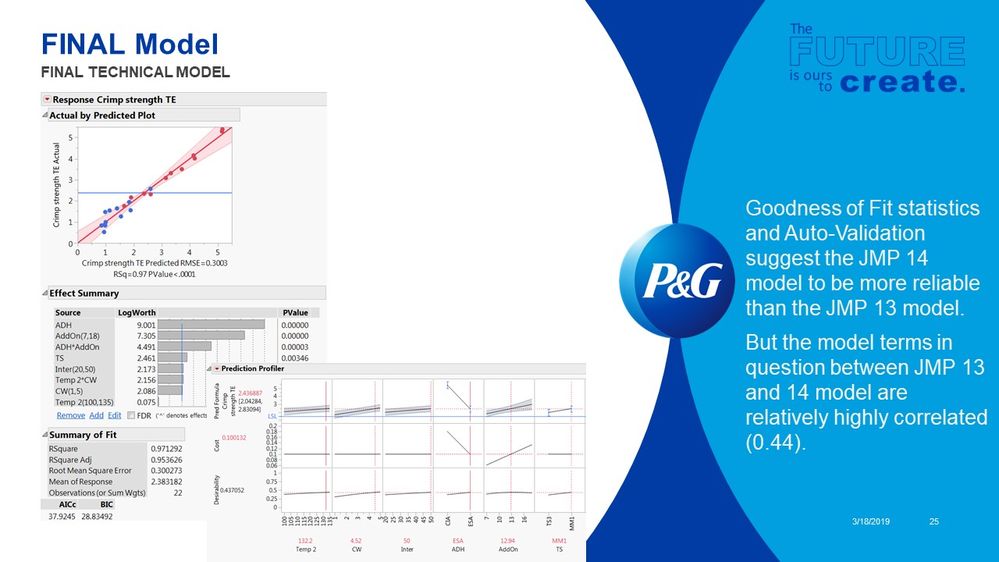

The case study discussed here will describe an attempt to combine two existing bonding technologies – gluing and thermoplastic fusion – in such a way that the finished pad remains stress-resistant while improving "pleasant" feel on skin. We will explain the team's decision making roadmap from problem definition to DoE finalization, including which constraints we had to respect, which performance targets we wanted to meet and why we chose to run a DSD eventually. Furthermore, we will discuss the DSD model building, Model selection via Auto-Validation and our final production process settings for the desired target.

(from: Brisbane's Best Fitness Classes For Women - Syle Magazines)

Sanitary pads should also stay laminated in work-out situations like above.