Digital Twin of a Manufacturing Process in a JMP data table

Voted Best ePoster by Summit attendees.

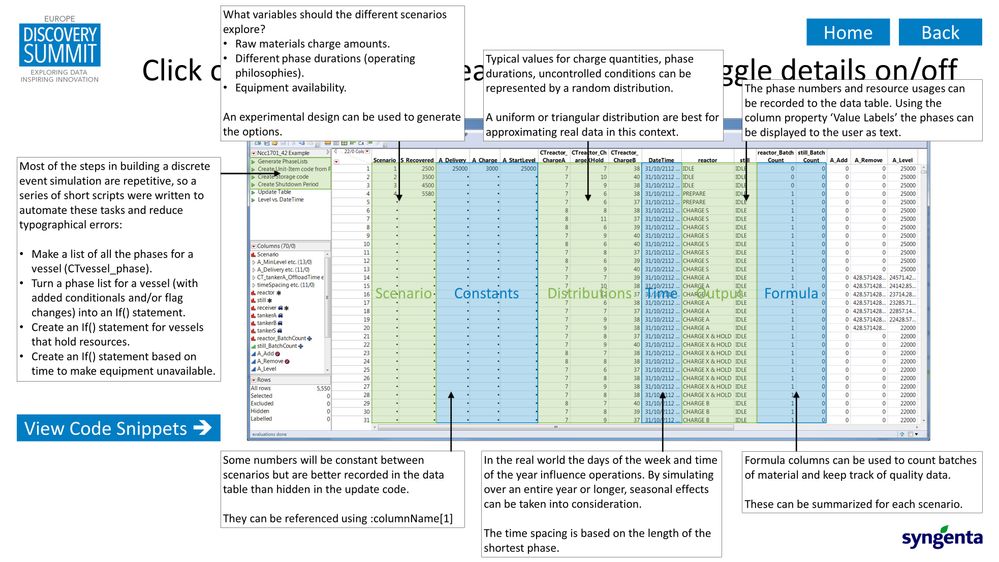

This poster will show how in seconds on a standard laptop, many months’ production can be simulated. Many of the unique features of a JMP data table make this possible (Column Groups, Hiding/Excluding Columns, Column Summary Statistics, Value Labels).

Manufacturing facilities are controlled using a mixture of computer automation and experienced operators. The ‘rules’ governing the control signals and how they lead to responses can be derived from recorded data (using the different JMP platforms) and approximated using column formula. The result is a digital representation of the manufacturing process which can be used to carry out Discrete Event Simulation (DES). The challenge comes in generating the control signals a row at a time whilst evaluating the responses which produces feedback loops.

The advantage of using a JMP data table is that any visualizations and analysis developed for the real process can be applied to the simulated result. Design of Experiments can be used to systematically see how the process might respond under different scenarios. An output derived from the responses such as equipment utilization can then be used to aid decision making. When the difference in cost options runs to six or seven-figures this is extremely valuable.

Also included are two prototypes of the model so you can understand the code better which is carrying out the table updates. One considers only recipe controlled items, the second includes tracking changes in levels with solvent recycling.

Voted Best ePoster by Summit attendees.

This poster will show how in seconds on a standard laptop, many months’ production can be simulated. Many of the unique features of a JMP data table make this possible (Column Groups, Hiding/Excluding Columns, Column Summary Statistics, Value Labels).

Manufacturing facilities are controlled using a mixture of computer automation and experienced operators. The ‘rules’ governing the control signals and how they lead to responses can be derived from recorded data (using the different JMP platforms) and approximated using column formula. The result is a digital representation of the manufacturing process which can be used to carry out Discrete Event Simulation (DES). The challenge comes in generating the control signals a row at a time whilst evaluating the responses which produces feedback loops.

The advantage of using a JMP data table is that any visualizations and analysis developed for the real process can be applied to the simulated result. Design of Experiments can be used to systematically see how the process might respond under different scenarios. An output derived from the responses such as equipment utilization can then be used to aid decision making. When the difference in cost options runs to six or seven-figures this is extremely valuable.

Also included are two prototypes of the model so you can understand the code better which is carrying out the table updates. One considers only recipe controlled items, the second includes tracking changes in levels with solvent recycling.