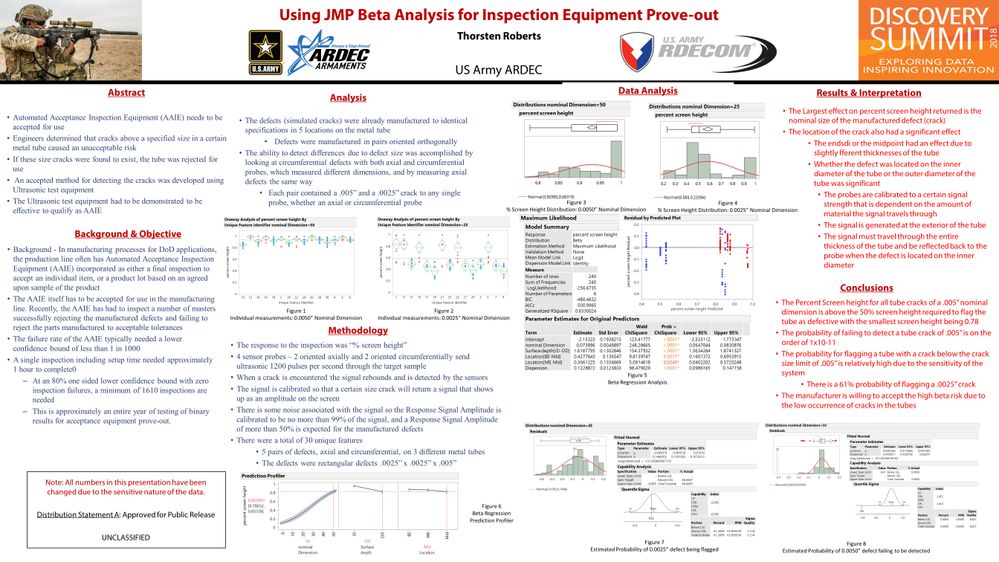

Thorsten Roberts, US Army ARDEC

Background - In manufacturing processes for DoD applications, the production line often has Automated Acceptance Inspection Equipment (AAIE) incorporated as either a final inspection to accept an individual item, or a product lot based on an agreed upon sample of the product. The AAIE itself has to be accepted for use in the manufacturing line. Recently, the AAIE has had to inspect a number of masters successfully rejecting the manufactured defects and failing to reject the parts manufactured to acceptable tolerances. The failure rate of the AAIE typically needed a lower confidence bound of less than 1 in 1000. IN this situation, a single inspection including setup time needed approximately 1 hour to complete. At an 80% one sided lower confidence bound with zero inspection failures, a minimum of 1610 inspections are needed. This is approximately an entire year of testing of binary results for acceptance equipment prove-out. Using alternate analysis of variable prove-out data, it is possible to qualify AAIE in much fewer trials.