This guide provides instructions on performing a capability analysis using the Distribution and Control Chart platforms. A process capability analysis is used to evaluate the performance of a process for a continuous variable to specifications (Lower and/or upper specification limit, and/or target). See Capability Analysis for Multiple Responses guide for performing process capability analyses on multiple process variables simultaneously.

Capability Analysis – from Distribution Platform

- From an open JMP data table, select Analyze > Distribution.

- Select one or more continuous variables from Select Columns, click Y, Columns. Here we chose ‘Weight’. Click OK to generate a histogram and summary statistics.

- From the red triangle next to the variable name, select Process Capability.

- Enter the specification limits.

- Specify options such as defining a Subgroup variable, using a historical sigma value, choosing a specific distribution to use. Click OK.

- Two sets of capability metrics are produced – Within Sigma Capability based on the within subgroup measure of variation (Within Sigma = 1.052) and Overall Sigma Capability based on the total variation in the data (Overall Sigma = 1.475).

- Estimates of the % of a process that would exceed the specification is provided based upon the fitted distribution (normal in this case) and the two different estimates of variation (Within and Overall). An additional estimate of this is provided based upon the actual number of observations in the data set that exceeded the specification limits.

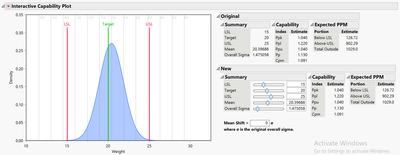

- Interactive Capability Plot is available under the red triangle next to the variable name.

The specification limits, mean, and the overall standard deviation can be changed and impact on the capability metrics and PPM outside of specification.

Note: Process Capability Platform can also be accessed from Analyze > Quality and Process > Process Capability.

Coating.jmp (Help > Sample Data Folder > Quality Control

Coating.jmp (Help > Sample Data Folder > Quality Control

Visit Quality and Process Methods > Process Capability in JMP Help to learn more.