- Subscribe

- Mark as read

- Mark as new

Learn JMP Events

Events designed to further your knowledge and exploration of JMP.- JMP User Community

- :

- Learn JMP

- :

- Learn JMP Events

- :

- Using the EMP Method for Measurement System Analysis

Using the EMP Method for Measurement System Analysis

Video was updated in September 2024. Audience Q&A begins ~time 28:39.

See how to:

-

Define MSA - An experiment designed to measure measurement system limitations to determine if measurement system is good enough to use or needs improvement

- Understand difference between Evaluting the Measurement Process (EMP) and Gage R&R

-

EMP provides a statistical approach for using measurement data effectively and creates gauge classificationsbased on probability of detecting a shift in the process

-

Classical Gauge R&R uses arbitrary thresholds for gauge classification (%R&R) but may lack information needed to use measurement data effectively

-

-

Use EMP to provide a statistical approach for using measurement data effectively for non-nondestructive case study

-

Build experimental design

-

Analyze the experiment data

-

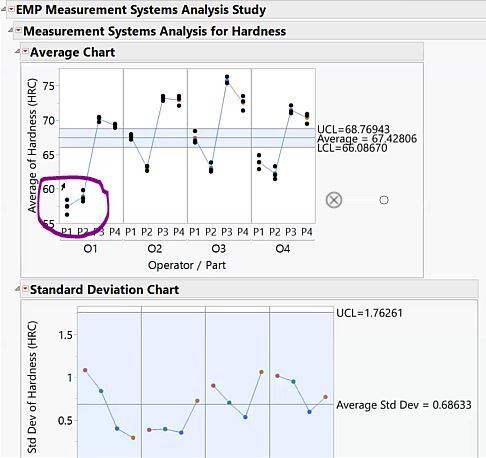

Interpret Average and Standard Deviation chart results

-

Determine variance components estimates

- Interpret Paralleism Plots, Bias Comparison, EMP Reports , including interclass correlations

- Understand gauge deployment recommendations based on probability of detecting a shift in the process

-

Questions answered by Clark Ledbetter @Clark_Ledbetter, Christian Stopp @ChristianStopp and Jason Wiggins @Jason_Wiggins at the live webinar:

Q: Is it possible to use EMP for destructive tests?

A: Not with EMP directly. We do have a video on using MSA for situations requiring destructive tests. If you think about a destructive test, you have to do some tricks to get your repeat measurements, and If I break something, how do I get a second measurement? Plus, I need repeat measurements to get repeatability and you can’t get those if something is broken.

A destructive measurement system that changes over the over the course of the time that you're doing the measurement system is like a temporal shift. You could handle that using JMP Functional Data Explorer. You could explore and use functional principle components to get your repeated measures. We can look into addressing that next year in Mastering JMP.

Q: If you're starting out from scratch, should you use EMP or Gauge R and R?

A: If you have the freedom to choose, I would go EMP. However, for automotives, according to AIAG1 guidelines, if your measurement system's variation is less than 10% of process's variation, then it is acceptable. The AIAG standards document is very useful and includes lots of wisdom for measurement studies and they relate to Gauge R&R.

Q: If I recall correctly, is %RR is based on the amount of variation from the measurement system relative to the maximum allowed based on specification limits (USL-LSL).

A: Yes. Improve the measurement process or open the spec limits is the fork in the road if improvement is warranted.

Q: When is it appropriate or when would you want to look at ICC with no bias?

A: If you understand the bias (like operator induced bias based on height of operator) and, subjectively, if you think the cost to shrink the bias is worth it.

Questions answered at a previous webinar on this topic:

Q: What do you mean by 'chunky data'?

A: Think of a histogram that describes a normal distribution. A "Chunky" histogram might have only 5 or 6 bins describing the distribution. "Non-chunky" data might have 15 or 20 bars (bins) describing the distribution, so it is much smoother.

Q: Does it matter in the average chart that one point was within the ULC/LCL?

A: No, it just means that that particular part is close to the overall average of the parts. You just want most of the parts outside the UCL/LCL range.

Q: Is the EMP methoday different than variability charts?

A: Using the gauge variability chart, you're essentially kind of looking at the same setup. So you could use that platform and it's generating, the gauge variability output. That would be very similar to the variability chart with the the means connected just by showing the data and then the line goes through through the middle. The graphic is similar. What you get in this case are the control limits and n>the ability to kind of infer that a are my are my parts outside the control limit.

Q: What if you have more factors?

A: You can add more factors (like multiple gauges, multiple plants, etc.) and you can declare those as Crossed or Nested factors. That is handled in the setup (see DOE for measurement systems in JMP), and then analyzed similarly to what Jason just did.

Q: In the Med. Device Industry, the FDA has warned that rounding is not allowed and is considered falsification of data. Now the question- is it a problem if we don't round?

A: The way you conduct any analysis in a controlled industry is specific to that industry, so following their guidelies is critical. You must discern what you can do from what you should do,

Resources

-

Don Wheeler papers from Statistical Process Controls Press

-

JMP course on MSA

-

MSA and EMP JMP documentation and examples

- Problems With the AIAG Gauge R&R Study by Don Wheeler

- Quality Digest columns by Don Wheeler

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us