Robust Regression Using Regular JMP 18 version powered by Python Integration

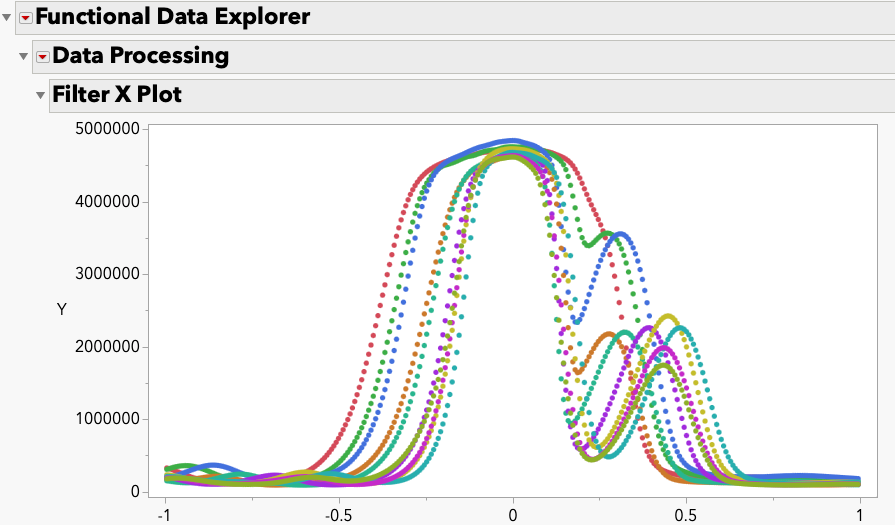

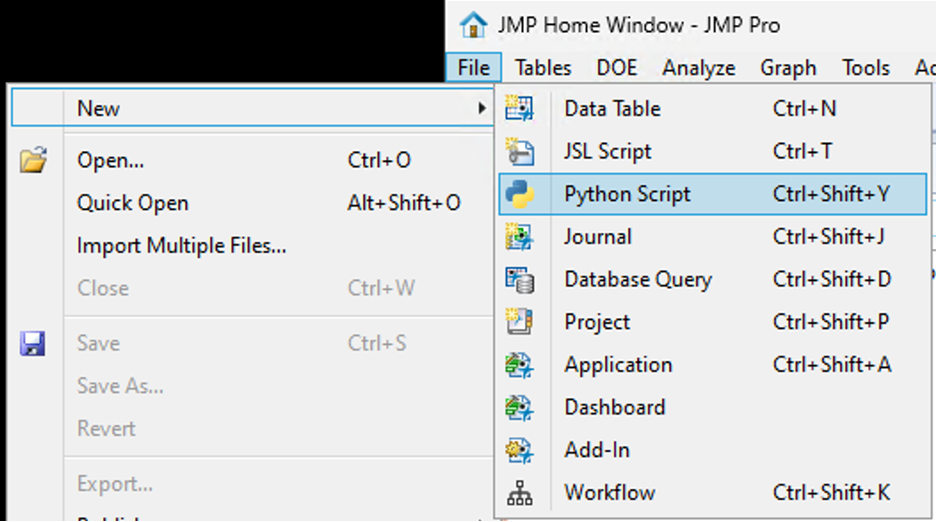

Enhance your regression analysis with the powerful combination of robust techniques and JMP 18, now featuring seamless integration with Python. Simple Case Study Here's a sample...

DaeYun_Kim

DaeYun_Kim

SamGardner

SamGardner

gail_massari

gail_massari

Valerie_Nedbal

Valerie_Nedbal

Richard_Zink

Richard_Zink KristenBradford

KristenBradford

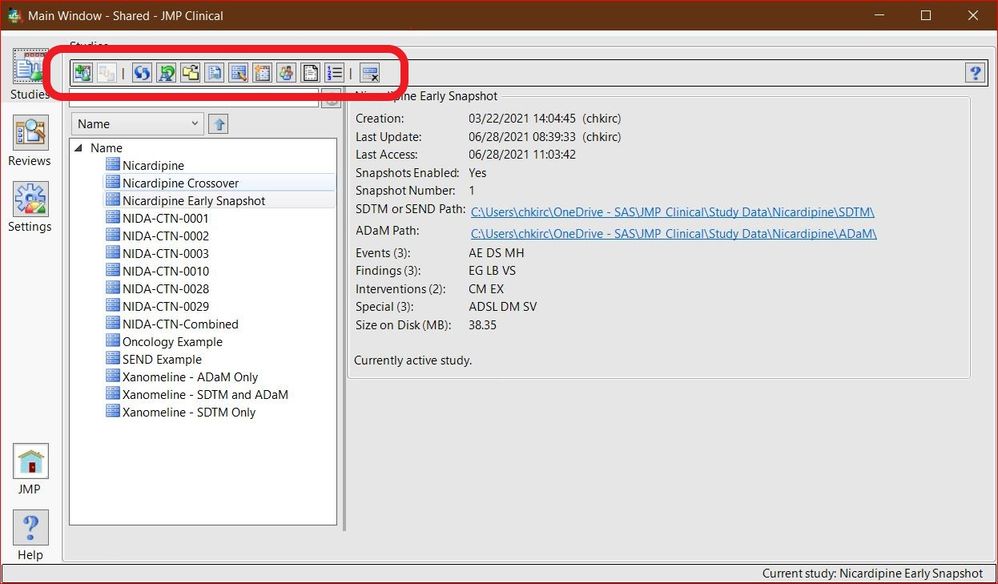

Chris_Kirchberg

Chris_Kirchberg

cweisbart

cweisbart

Paul_Nelson

Paul_Nelson

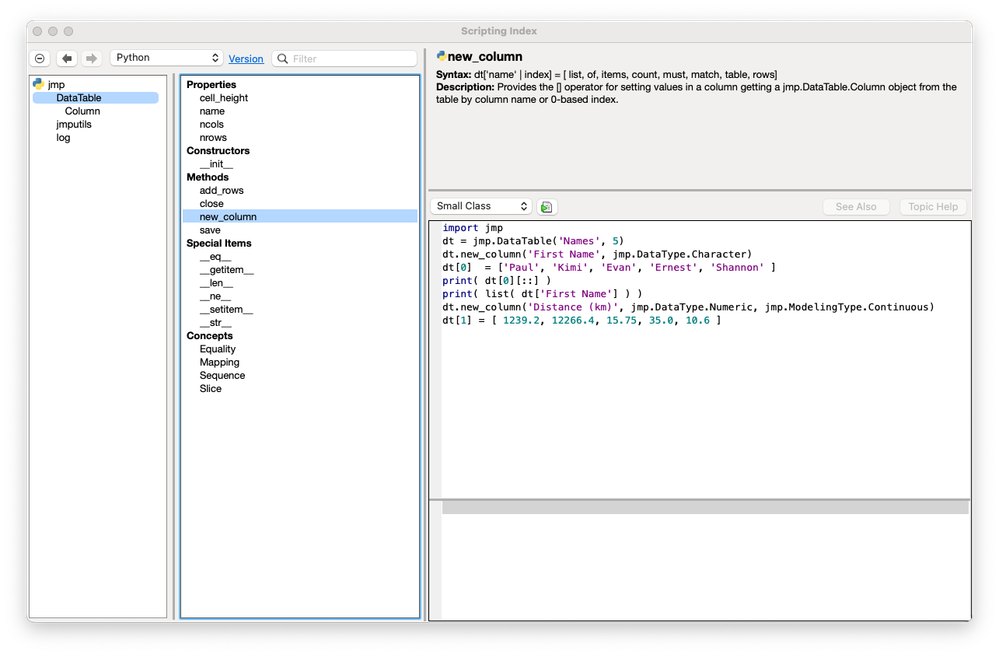

Craige_Hales

Craige_Hales

anne_milley

anne_milley

Di_Michelson

Di_Michelson

JohnPonte

JohnPonte Masukawa_Nao

Masukawa_Nao

Jed_Campbell

Jed_Campbell LauraCS

LauraCS MarilynWheatley

MarilynWheatley