- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Discussions

Solve problems, and share tips and tricks with other JMP users.- JMP User Community

- :

- Discussions

- :

- Re: Process capability forecast

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Process capability forecast

Hi,

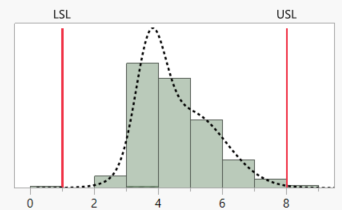

I have calculated the process capability in JMP for this process with the mixture of 2 normals distribution. Our current ppk is 0,94. We plan to improve the measuring system cause it has currently a high variation. Now I want to explore how much improvement for the measuring system is needed (measuring system variation is actually 2.5).

Does anybody know how this simulation can be done in JMP?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Process capability forecast

I have more questions than I have answers. You can certainly input a sigma value in the Historical data section of process capability to get the "predicted" results.

How do you know the measurement system variation is 2.5? Is this the combined repeatability and reproducibility standard deviation? Is the measurement system variation consistent? Why wouldn't you do anything you could to reduce the variation of the measurement system?

I don't understand "mixture of 2 normals distribution". Why are there 2 normal distributions? Are the specs appropriate?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Process capability forecast

Thanks for your answer. I can understand that you have more questions than answers :D

The measurements system variation is calculated with the current resolution of the measuring system. Unfortunately we don't have a MSA done.

We have do decide which kind of measuring system would be sufficient for the goal to improve the ppk to 1.33 but I understand your comment. We should try to achieve the best possible improvement.

The mixture of 2 normals was the best fit but I have checked it and found out that lognormal is also a possible good fit so I'm gonna use this distribution.

I'll try to check if I can solve this issue with the predicted results.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Process capability forecast

Here's my thoughts,

The total variation you are seeing in your histogram is Variance(total)=Variance(part)+ Variance(Measuement system[MS]).

If you know the variance of the MS as well as the total you can solve for the variance of the part.

From that you can then create a random data column where you create a fake data distribution based upon your new variance total where you use the previous calculated part variance and the estimated new MS variance. You could make multiple columns stepping down the MS variance and then use the process capability platform to look at all the different step downs and see what amount would be needed to reach a desired Ppk.

Hope this make sense!

Steve

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Get Direct Link

- Report Inappropriate Content

Re: Process capability forecast

Hi Steve,

thanks for your answer. Your idea sounds quite good and easy for me. I'll try it and I'll reply if it worked.

Recommended Articles

- © 2026 JMP Statistical Discovery LLC. All Rights Reserved.

- Terms of Use

- Privacy Statement

- Contact Us