Level: Beginner

Lisa Estey, Senior Staff Scientist, IDEXX Laboratories

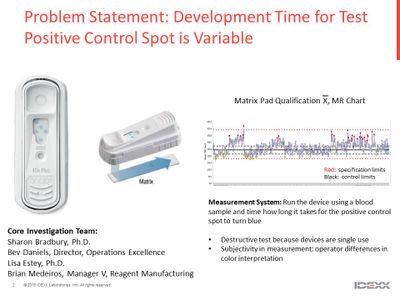

Sharon Bradbury, Senior Staff Scientist, Beverly Daniels, Director, Operations Excellence, Brian Medeiros, Reagent Manufacturing Manager, IDEXX Laboratories

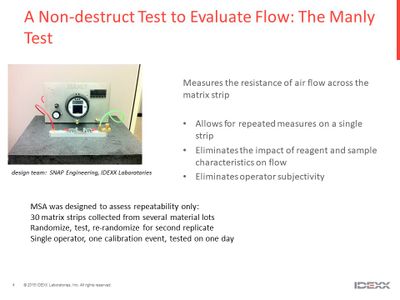

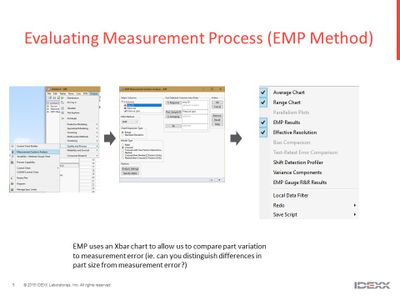

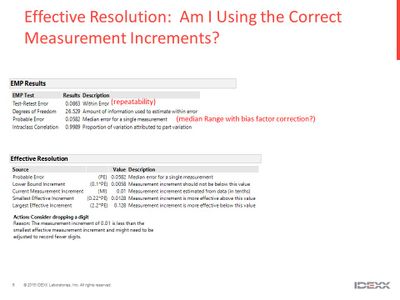

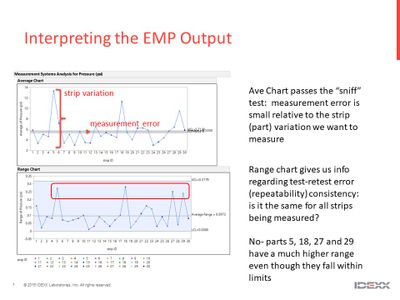

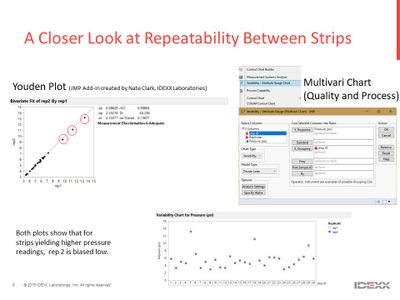

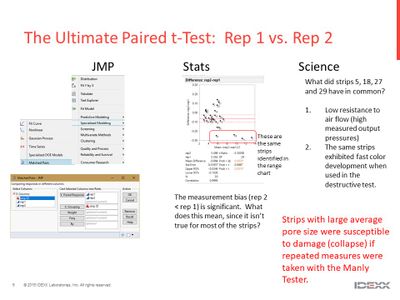

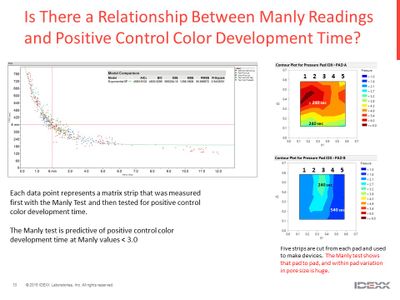

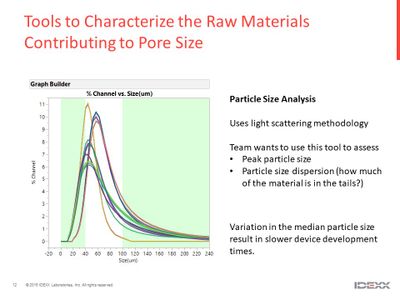

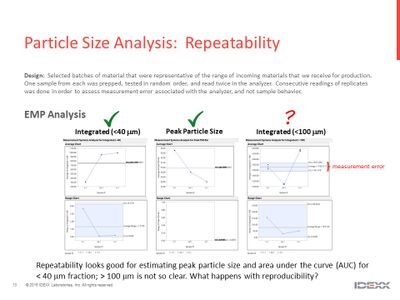

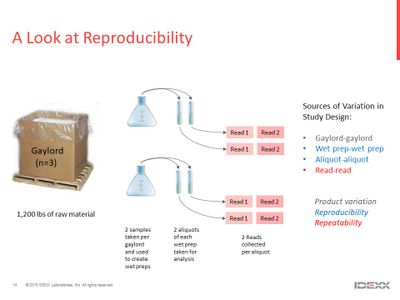

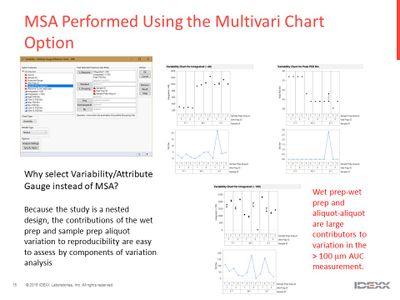

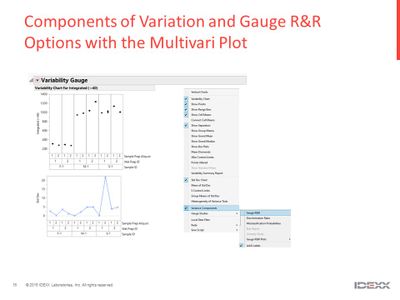

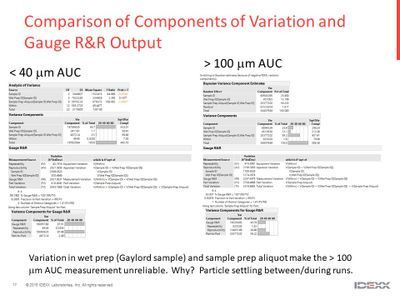

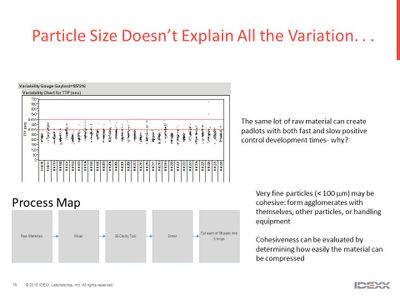

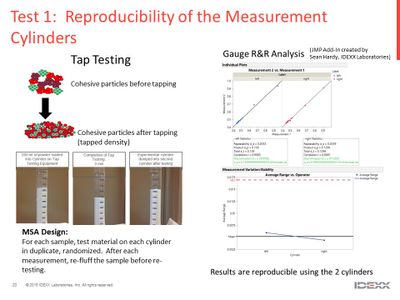

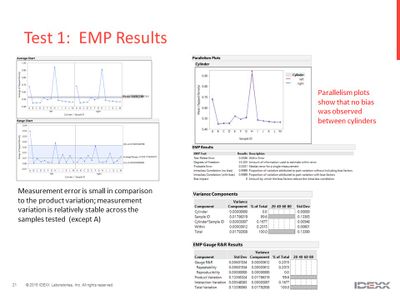

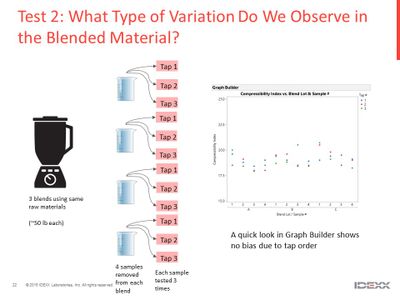

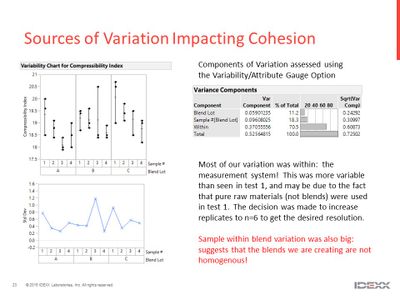

Measurement system analysis (MSA) is a statistical tool commonly used in industry by process and quality engineers. Through MSAs, operators gain an understanding of measurement uncertainty as it relates to repeatability, accuracy/bias and the components of variation that may influence test reproducibility. The introduction of Six Sigma methodologies at IDEXX expanded the use of MSAs by product development and problem-solving teams. Here we will examine three gauges posing challenges to the teams and demonstrate the JMP tools used to assess their performance, including Graph Builder, Gauge R & R, EMP and Variance Components. The gauges were adapted for use as analytical tools to understand sources of manufacturing variation in porous membranes used in our point of care diagnostic devices. These MSAs demonstrate common issues observed with destructive tests, and the importance of sample homogeneity when characterizing a new measurement system.