Design and Analysis of a Multiple Response Mixture Experiment for a Dry Etch Wafer Process

Level: Intermediate

Designed experiments for dry etch equipment present challenges for semiconductor engineers. First, because the total gas flow rate is often fixed, a mixture design must be used to honor the constraints imposed by this type of design. These types of designs are not commonly seen in the Semiconductor industry. Second, as is often the case with these experiments, the investigator is interested in optimizing more than one variable. In this presentation, you will see an example of how to design and analyze a seven-factor experiment for a dry etch tool and simultaneously optimize an overall wafer target value while minimizing within wafer variability.

Overview

-

Eight factor experiment for a dry etch process

- Three process gases: A, B, C

- Five process factors: power, pressure, temperature, time, total flow

- The experimenter was interested in both the gas ratios and the total gas flow. To keep total flow and gas ratios as uncorrelated as possible, a mixture design was used.

- To keep total flow and gas ratios as uncorrelated as possible, a mixture design was used.

- In addition, the experimenter wanted to bound the ratio for two of the gases between an upper and lower value.

- The third gas, C, was to make up no less than 10% and no more than 25% of the total mixture.

What is a Mixture Design?

- A mixture design is used when the quantity of two or more experimental factors must sum to a fixed amount.

- The inclusion of non-mixture components (i.e., factors that are not part of the mixture) makes designing this experiment challenging.

- Mixture designs emphasize prediction over factor screening. For that reason, mixture factors are not removed from the experiment even when they are not significant (they may be set to 0, however).

Mixture Design Challenges

- Effect are highly correlated and are harder to estimate.

- Squared mixture terms are confounded with (are a linear function of) mixture factor main effects and two factor interactions.

- Main effects for non-mixture factors are correlated with the two factor interactions between that non-mixture factor and the mixture factors.

- Focusing on prediction and use of the Profiler (instead of parameter estimation and significance) makes designing and interpreting mixture experiments much easier.

Experimental Responses

| Response | Goal |

| ER | Target=100 |

| ER Std | Minimize |

Experimental Factors

| Response | Low | High |

| Power | 25 | 75 |

| Press | 100 | 200 |

| Temp | 25 | 40 |

| time | 30 | 45 |

| Total Flow | 80 | 120 |

| Gas A | 0 | 1 |

| Gas B | 0 | 1 |

| Gas C | 0.1 | 0.25 |

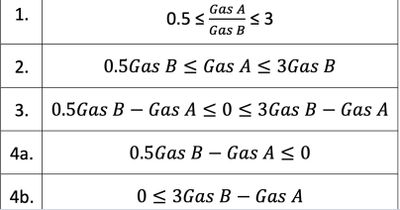

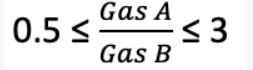

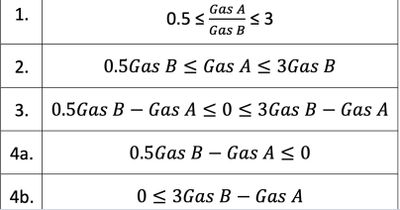

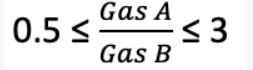

Experimental Constraints

Level: Intermediate

Designed experiments for dry etch equipment present challenges for semiconductor engineers. First, because the total gas flow rate is often fixed, a mixture design must be used to honor the constraints imposed by this type of design. These types of designs are not commonly seen in the Semiconductor industry. Second, as is often the case with these experiments, the investigator is interested in optimizing more than one variable. In this presentation, you will see an example of how to design and analyze a seven-factor experiment for a dry etch tool and simultaneously optimize an overall wafer target value while minimizing within wafer variability.

Overview

-

Eight factor experiment for a dry etch process

- Three process gases: A, B, C

- Five process factors: power, pressure, temperature, time, total flow

- The experimenter was interested in both the gas ratios and the total gas flow. To keep total flow and gas ratios as uncorrelated as possible, a mixture design was used.

- To keep total flow and gas ratios as uncorrelated as possible, a mixture design was used.

- In addition, the experimenter wanted to bound the ratio for two of the gases between an upper and lower value.

- The third gas, C, was to make up no less than 10% and no more than 25% of the total mixture.

What is a Mixture Design?

- A mixture design is used when the quantity of two or more experimental factors must sum to a fixed amount.

- The inclusion of non-mixture components (i.e., factors that are not part of the mixture) makes designing this experiment challenging.

- Mixture designs emphasize prediction over factor screening. For that reason, mixture factors are not removed from the experiment even when they are not significant (they may be set to 0, however).

Mixture Design Challenges

- Effect are highly correlated and are harder to estimate.

- Squared mixture terms are confounded with (are a linear function of) mixture factor main effects and two factor interactions.

- Main effects for non-mixture factors are correlated with the two factor interactions between that non-mixture factor and the mixture factors.

- Focusing on prediction and use of the Profiler (instead of parameter estimation and significance) makes designing and interpreting mixture experiments much easier.

Experimental Responses

| Response | Goal |

| ER | Target=100 |

| ER Std | Minimize |

Experimental Factors

| Response | Low | High |

| Power | 25 | 75 |

| Press | 100 | 200 |

| Temp | 25 | 40 |

| time | 30 | 45 |

| Total Flow | 80 | 120 |

| Gas A | 0 | 1 |

| Gas B | 0 | 1 |

| Gas C | 0.1 | 0.25 |

Experimental Constraints